There are many factors that affect the smoothness of alloy saw blades

There are many factors that affect the smoothness of alloy saw blades.

Many customers hope that the smoothness of alloy saw blades can reach a mirror effect, which is not only for aesthetic purposes, but also reduces friction between the alloy and the product, thereby improving the wear resistance of the alloy saw blades.

Based on practical work experience, we have found that the following factors can affect the smoothness of alloy saw blades:

1. Grinding wheel grit

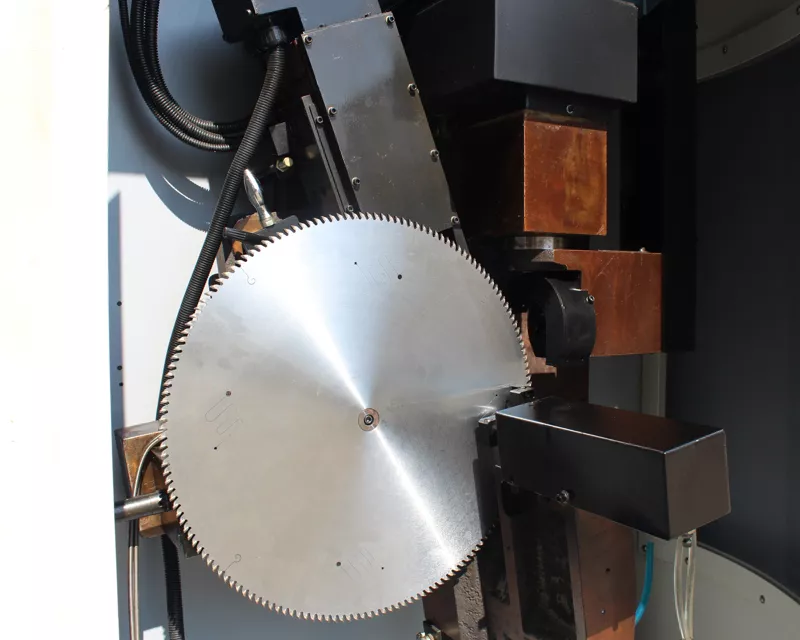

In general, the grinding process of alloy saw blades is divided into two or three stages. The first few stages are rough grinding, and the last stage is fine grinding. If a grinding wheel with finer grit is used, the resulting texture will be finer and the product will appear brighter to the naked eye.

2. Grinding wheel speed.

DM100 face and top grinding machine

The higher the speed of the grinding wheel, the shorter the contact and friction time with the alloy saw blade, and the less chance of forming texture on its surface.

3. Grinding fluid concentration.

The grinding fluid used in the processing process plays an auxiliary role. However, if the concentration is too low or the viscosity is too high, it may affect the surface smoothness of the alloy saw blade.

High-grade alloy grinding fluid

4. The alloy saw blade is composed of many particles of different sizes.

The finer the particles, the smaller the gaps between them, and the greater the compactness of the product. It is also easier to polish during the polishing process.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.