The basis of cutting is grinding.

Grinding and cutting are two common methods used in metal processing.

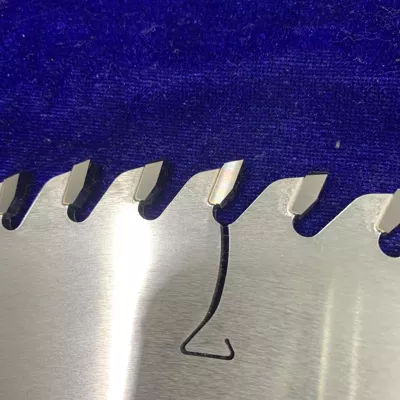

Grinding is usually used to reduce the surface unevenness of the material and cut the material to the desired shape and size. Cutting directly removes the material from the whole body to form the desired shape and size. Although both methods involve cutting the material, their processes and tools are different.

Grinding requires the use of special abrasive tools and durable coolant.

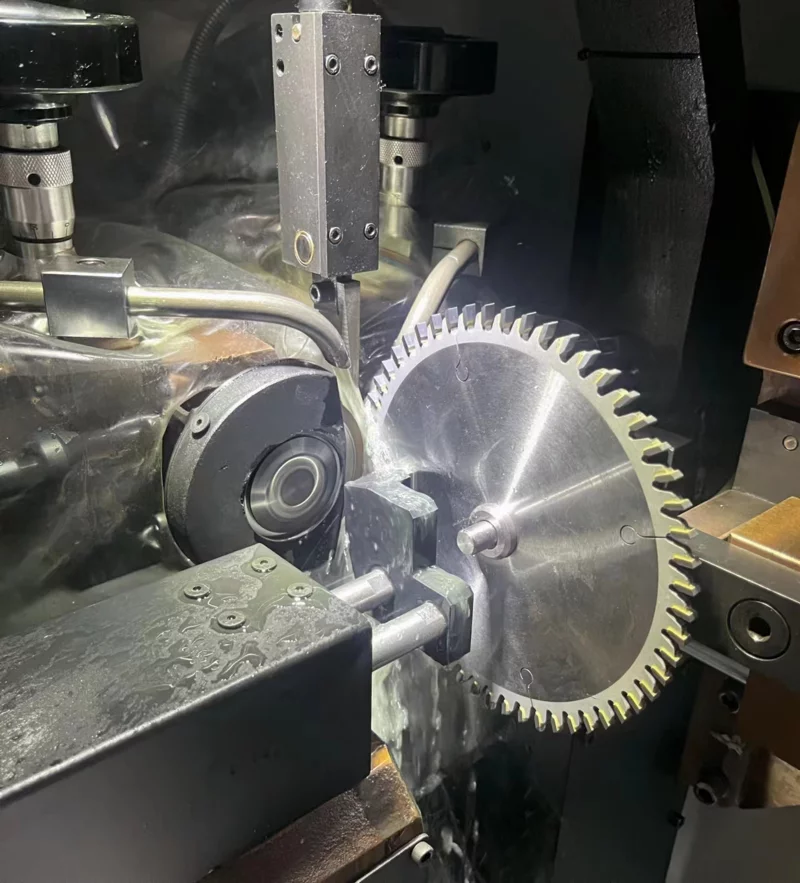

Coolant is widely used to cool and lubricate the abrasive tools and objects to be cut, reduce load, prevent overheating, and improve the cutting effect and life. Therefore, coolant must have excellent heat dissipation and lubrication performance. In contrast, cutting oil requires strong cleaning ability and antibacterial function. Due to the large amount of dust and debris produced during the cutting process, using cutting oil can keep the processed objects clean and prevent bacterial growth. In addition to the differences in tools and fluids, there are also differences in manufacturing methods: repeatedly polishing the contact surface is generally taken when precision control is carried out;while completing the required size and shape in a one-time operation is a typical example. Because this rapid operation process may give more pressure to the user and the fluid itself.

MCC650E double side grinding machine

In summary, no matter what field or other field needs to choose the best equipment and related facilities for its own target task, including the selection of appropriate fluids and so on.

Although as a general phenomenon we know that those things can be used for cooling and other aspects of operation, but in fact everyone should be careful when choosing various products according to what kind of results they want to achieve, so as to ensure that you buy the best quality products.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.