Requirements for use

1. Choose the appropriate saw blade according to the equipment's design requirements.

2. Have professional operators install and use it, wear work clothes, and wear protective glasses, ear protectors, etc.

3. During work, ensure that the workpiece is fixed, the profile positioning is correct for the cutting direction to prevent abnormal cutting, do not apply side pressure or cut curves, feed the blade smoothly, avoid sharp contact between the blade and the workpiece, which may cause the saw blade to break or the workpiece to fly out, causing accidents.

4. During work, if abnormal noise and vibration, rough cutting surface, or strange odor are detected, the operation must be terminated immediately, check in time, troubleshoot to avoid accidents.

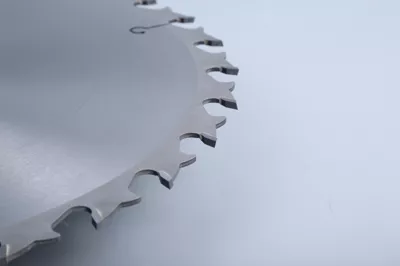

5. Do not feed too fast when starting and stopping cutting to avoid tooth breakage and damage.

6. If cutting aluminum alloy or other metals, use special cooling lubricant to prevent the saw blade from overheating, causing gumming, and other damage, affecting cutting quality.

7. Ensure that the equipment's chip groove and slag suction device are unobstructed to prevent slag buildup, affecting production and safety.

8. When dry cutting, do not cut continuously for a long time to avoid affecting the saw blade's service life and cutting effect; when wet cutting, water cutting should be used, to prevent electric leakage.

Installation requirements

Edit

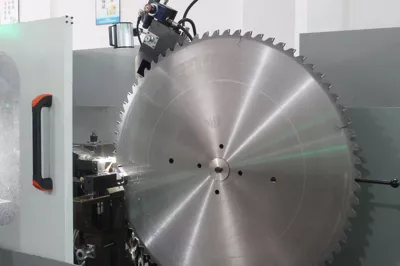

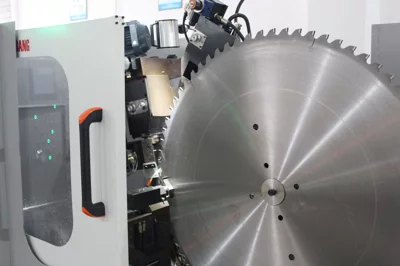

1. The equipment is in good condition, the spindle is not deformed, and there is no runout, the installation is secure, and there is no vibration, etc.

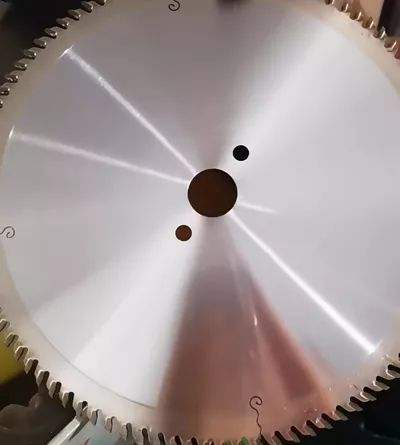

2. Check if the saw blade is damaged, if the tooth profile is complete, if the saw blade is flat and smooth, and if there are any other abnormal phenomena to ensure safety during use.

3. When assembling, ensure that the direction of the saw blade arrow is the same as the rotation direction of the equipment spindle.

4. When installing the saw blade, keep the axis, chuck, and flange clean, ensure the inner diameter of the flange is the same as the inner diameter of the saw blade, ensure that the flange and the saw blade are tightly connected, install the positioning pin, and tighten the nut. The size of the flange should be appropriate, and the outer diameter should not be less than 1/3 of the saw blade diameter.

5. Before starting the equipment, ensure safety, operate the equipment by one person, rotate it slowly, check if the equipment turns in the correct direction, check for vibration, after installing the saw blade, run it empty for a few minutes, and work normally without slipping, swinging, or bouncing after normal operation.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.