Raise knowledge Why do machine tools release stress

There has always been a saying in the machine tool industry that machine tools need to release stress, and the higher the precision of the machine tools, the more attention needs to be paid to stress release. So why do we need to release stress? How long should the stress be released? How to release stress properly in machine tools? Don't worry, let's take a look at these questions one by one in this article.

▌ What is stress?

When an object deforms due to external factors (such as force, humidity, temperature changes, etc.), internal forces are generated between different parts of the object to resist the action of these external factors and try to restore the object to its original position before deformation.

The stress that machine tools need to release is called mechanical stress, which is generated during the thermal forming process of the bed and other components. Due to the requirement of high precision machining accuracy of machine tools, which needs to reach the level of micrometers or even nanometers, the deformation errors caused by the internal stress generated in casting are unacceptable. Therefore, machine tools need to release stress. In simple terms, relevant components of the machine tool will generate stress during thermal processing, and this stress will cause certain deformation of the components, which will affect the accuracy of the machine tool. Therefore, the higher precision the machine tool is, the more stress release is needed to ensure the accuracy and stability of the machine tool.

▌ How long should stress in machine tools be released?

It is generally known that stress in machine tools is released through static methods. It is rumored that in the past, some machine tool manufacturers would submerge the castings in the sea or bury them underground to fully release the stress. However, there is no reliable evidence to support this claim, so it's just for reference. So how long should stress in machine tools be released?

When searching for information online, there are various answers, ranging from a few months to seven or eight years. After consulting some professional papers, my answer is that stress release in machine tools takes several months to several years depending on different metal components, taking into account factors such as volume, shape, etc.

It should be noted that the environment for stress release should be considered according to the specific situation of the components. It is not always possible to achieve the best results outdoors or in some extreme environments. Of course, with technological advances, there are now more and more methods for stress release, and the time required is getting shorter.

(All the equipment of the Ling Bang Company uses the nodular cast iron and the static method is used to release the pressure)

▌ How to release stress?

As mentioned earlier, static release is one of the methods to release stress, but this method is used less and less now. The reason is simple: static release takes too long and the cost is too high for machine tool manufacturers. With technological advances, there are now more and more ways to release stress in machine tools, and the time required is getting shorter. Before discussing specific methods of stress release, it should be emphasized that stress release is generally completed before assembly. After assembly, the whole machine generally needs to rest for about 10 to 20 days, following the instructions of different manufacturers.

Generally speaking, high-precision machine tools will use materials such as marble for the bed, which are less prone to stress. Machine tools made of metal materials now also use methods such as shot blasting, vibration, and roller burnishing to remove stress. Shot blasting uses projectiles to impact the surface of the workpiece and implant residual compressive stress. Vibration uses a vibrator to resonate with the workpiece to eliminate stress. Roller burnishing applies pressure to the surface of the workpiece using certain roller burnishing tools to eliminate stress. In addition, stress can also be eliminated through methods such as thermal aging, explosion, thermoshock aging, and ultrasonic aging.

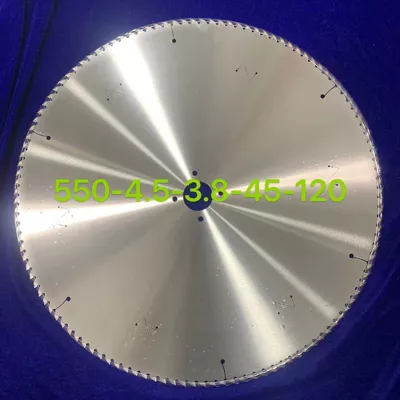

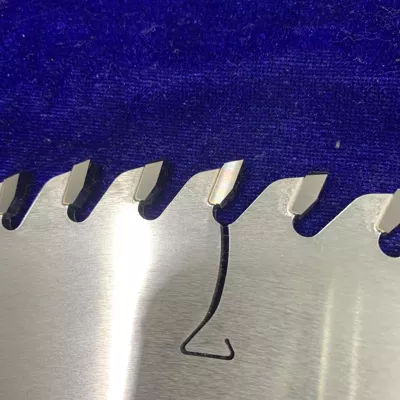

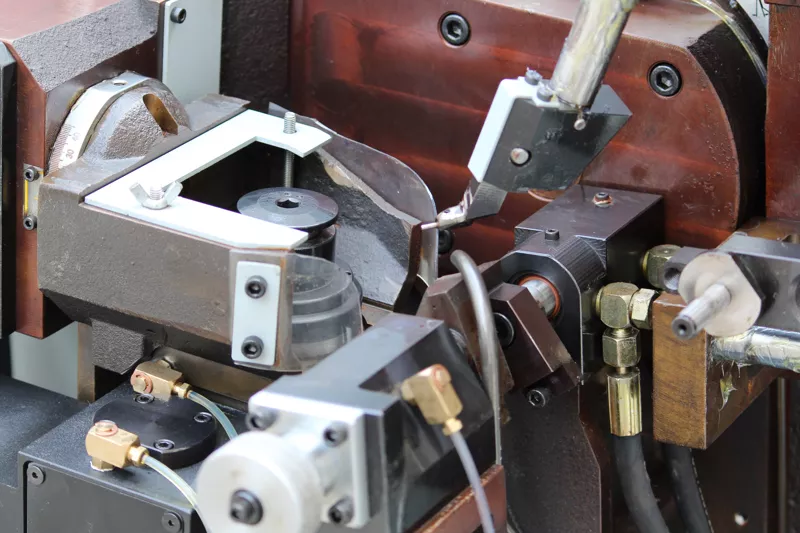

DM100 face and top grinding machine

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.