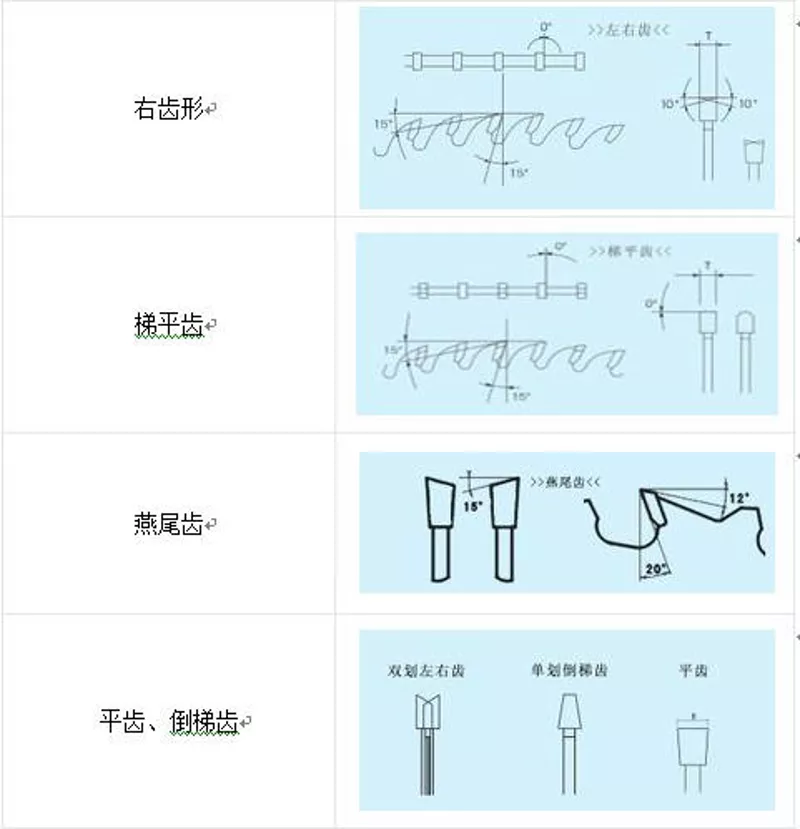

The selection of saw blade tooth angle is crucial in determining the cutting quality

The selection of saw blade tooth angle is crucial in determining the cutting quality.

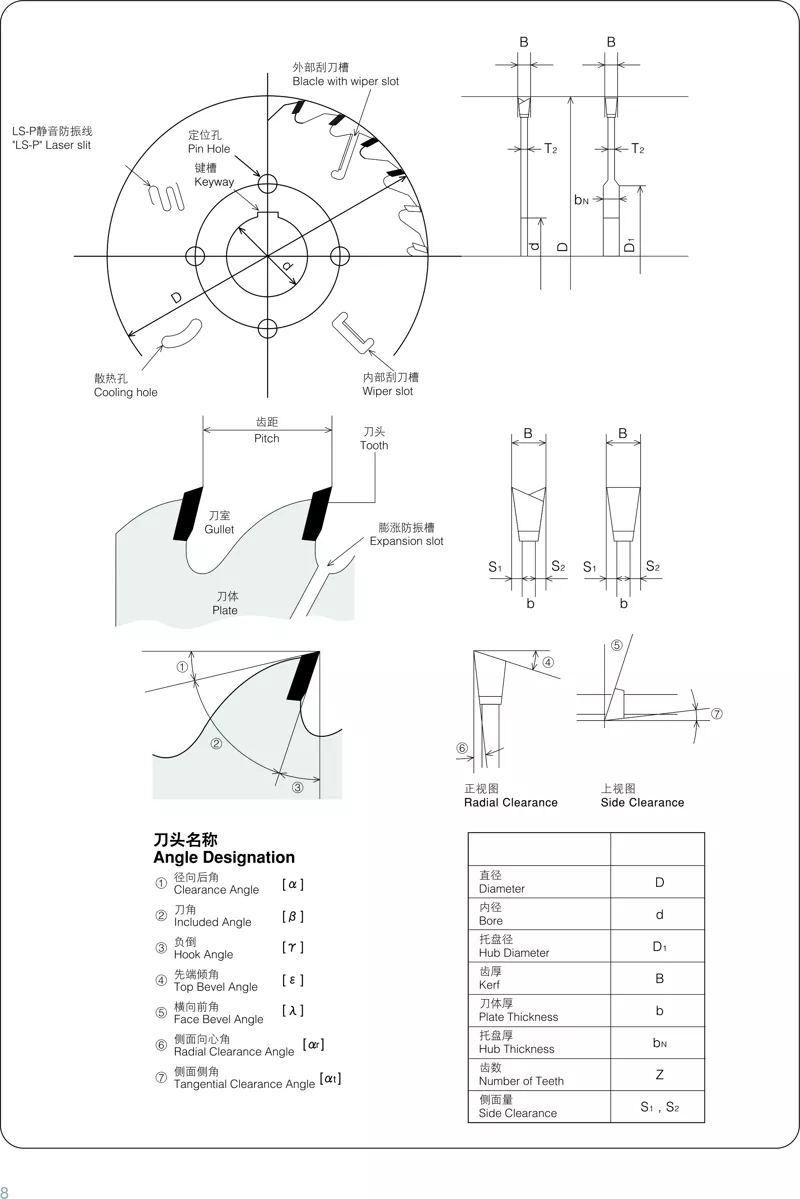

It is essential to choose the correct primary angle parameters such as front angle, back angle, and wedge angle.

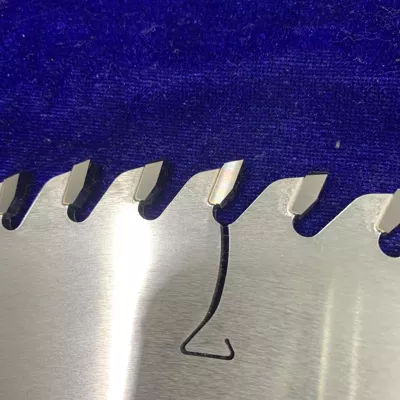

1. The front angle primarily affects the force consumed by sawdust during sawing. A larger front angle results in better cutting sharpness, lighter sawing, and easier material pushing. Generally, when the material is softer, a larger front angle is chosen, and vice versa.

2. The angle of the saw teeth refers to the position of the teeth during cutting. The angle of the teeth affects the performance of the cutting. The angles that have the most significant impact on cutting are the front angle (γ), back angle (α), and wedge angle (β). The front angle (γ) is the angle at which the teeth enter the material. A larger front angle enables quicker cutting. The front angle is generally between 10-15°.

3. The back angle is the angle between the teeth and the already processed surface. Its function is to prevent friction between the teeth and the processed surface. A larger back angle reduces friction and results in a smoother finished product. The back angle for hard alloy saw blades is generally set at 15°. The wedge angle is derived from the front and back angles. However, the wedge angle should not be too small, as it plays a role in maintaining tooth strength, heat dissipation, and durability. The sum of the front angle (γ), back angle (α), and wedge angle (β) is equal to 90°.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.