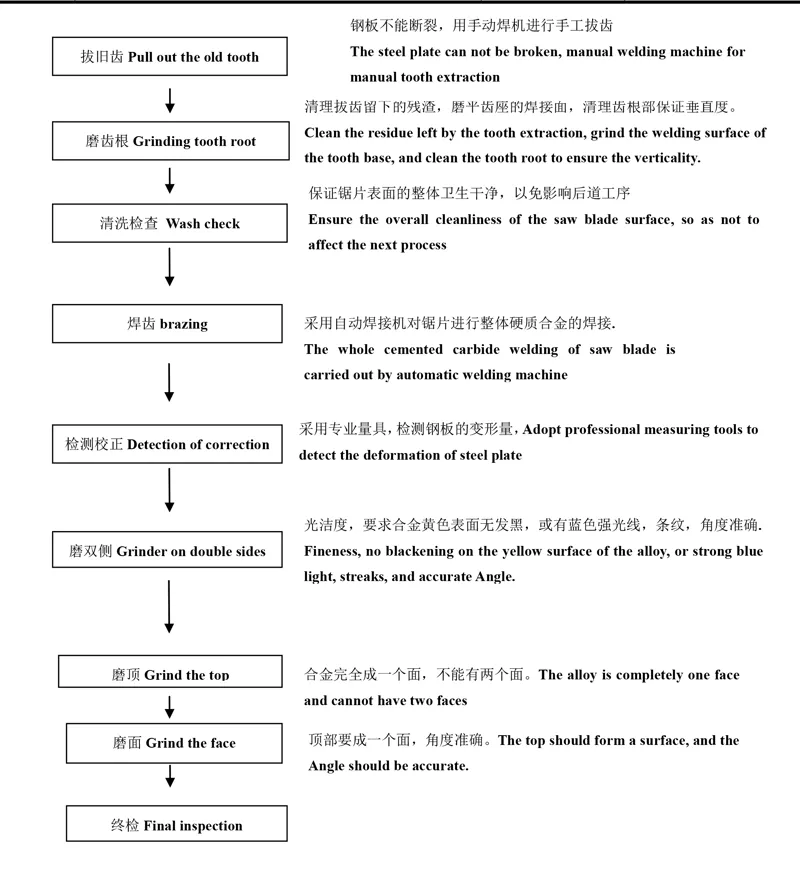

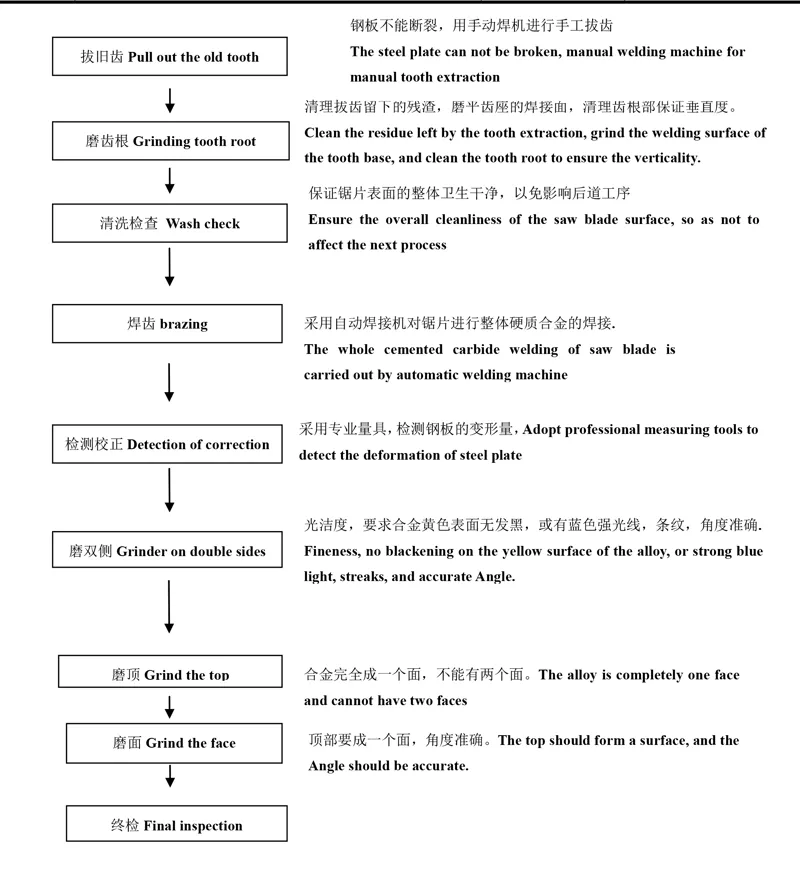

Circular saw blade reconditioning manufacturing process

Pull out the old tooth

The steel plate can not be broken , manual welding machine for manual tooth extraction

Clean the residue left by the tooth extraction , grind the welding surface of

Grinding tooth root

the tooth base , and clean the tooth root to ensure the verticality .

Wash check

Ensure the overall cleanliness of the saw blade surface , so as not to

affect the next process

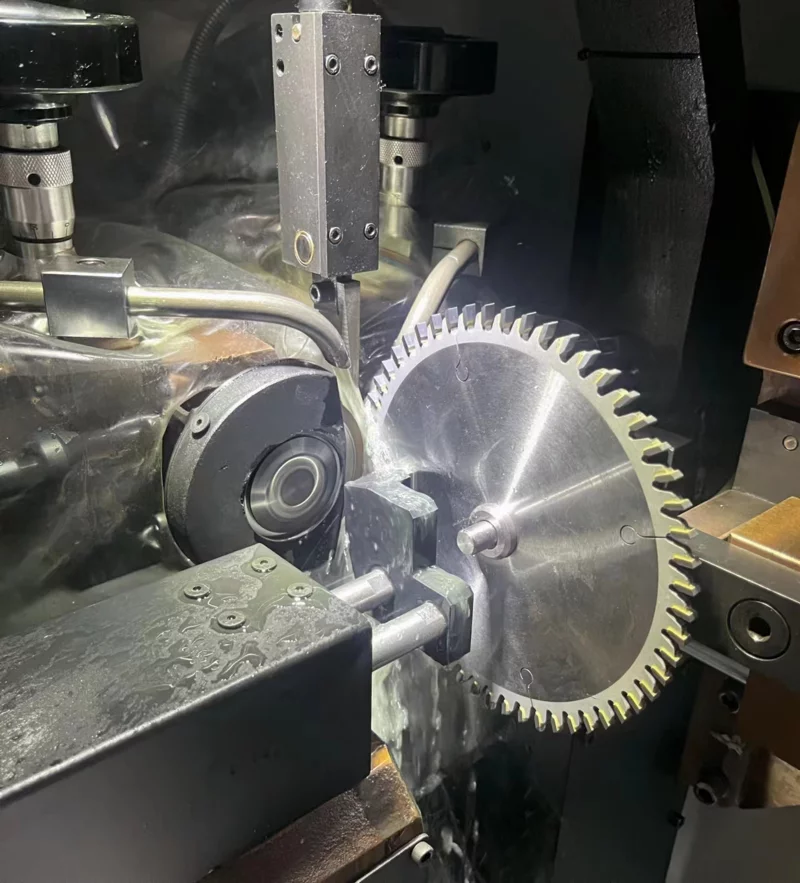

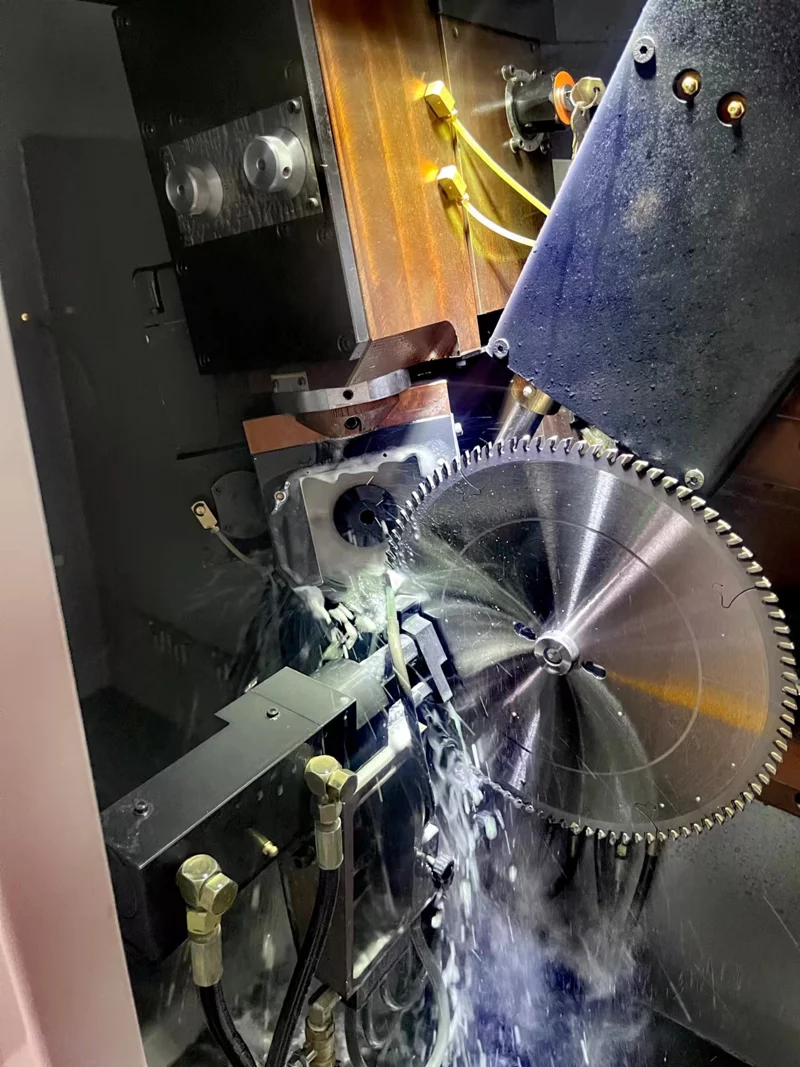

brazing

The whole cemented carbide welding of saw blade is

carried out by automatic welding machine

Adopt professional measuring tools to detect the deformation of steel plate

Detection of correction

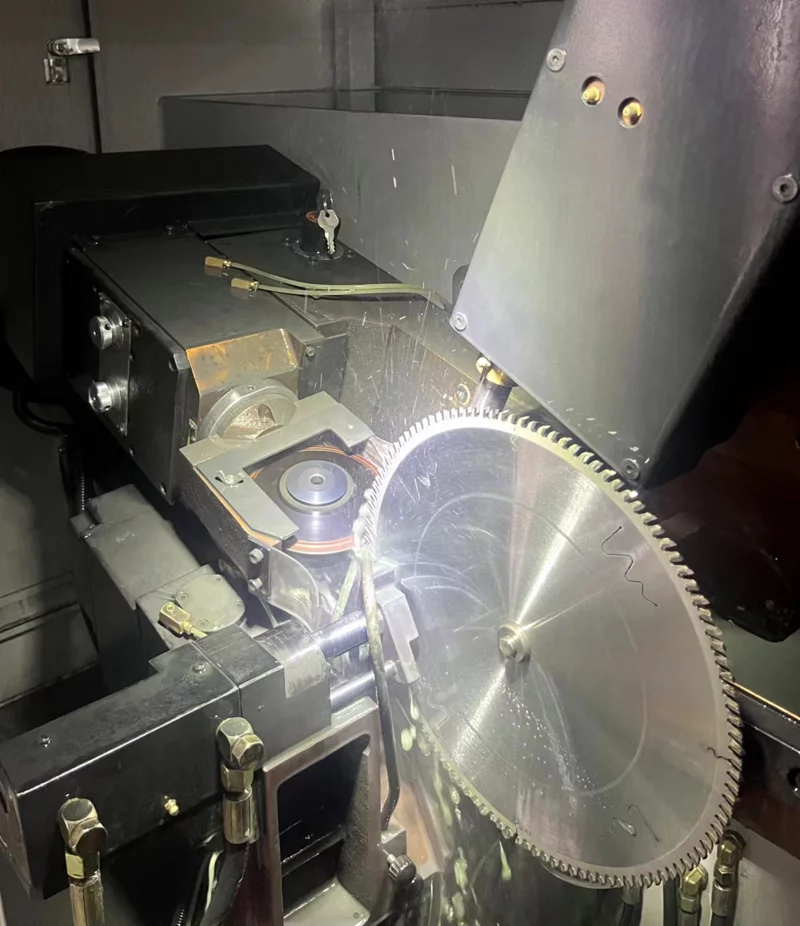

Fineness , no blackening on the yellow surface of the alloy , or strong blue light , streaks , and accurate Angle .

Grinder on double sides

Grind the top

The alloy is completely one face

and cannot have two faces

Grind the face

The top should form a surface , and the

Angle should be accurate .

Final inspection

- For more details on the manufacturing process, please click the following information:

- Carbide Circular Saw Blade Production Process - Saw Blade Substrate Inspection 01

- Carbide Circular Saw Blade Production Process - Saw Blade Substrate Inspection 02

- Carbide Circular Saw Blade Production Process - Saw Blade Substrate Inspection 03

- Carbide Circular Saw Blade Production Process - Saw Blade Substrate Inspection 04

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.