Introduction to Light Guide Plate Cutting Saw Blade

The light guide plate, a leader in the field of optics, has been widely used in multiple industries such as lighting, displays, and communication. Its main function is to accurately guide light to the desired location, providing convenience for our daily life and work. In the manufacturing process, cutting is a crucial step. In order to achieve high-quality cutting results, the light guide plate cutting saw blade has become an indispensable tool.

As the name suggests, the light guide plate cutting saw blade is a precision tool designed specifically for cutting light guide plates. It relies on high-hardness cutting materials such as steel or tungsten carbide to ensure stable and efficient cutting work. These high-quality materials not only have excellent wear resistance but also possess outstanding cutting performance, enabling smooth cutting of light guide plates.

Furthermore, the design and application of the light guide plate cutting saw blade also take into consideration ease of operation and work efficiency. Its precise cutting shape and size ensure smooth and accurate edges of the light guide plate, meeting various optical requirements. Meanwhile, the efficient cooling and lubricating system effectively reduces the working temperature of the saw blade, prolongs its lifespan, and ensures cutting stability.

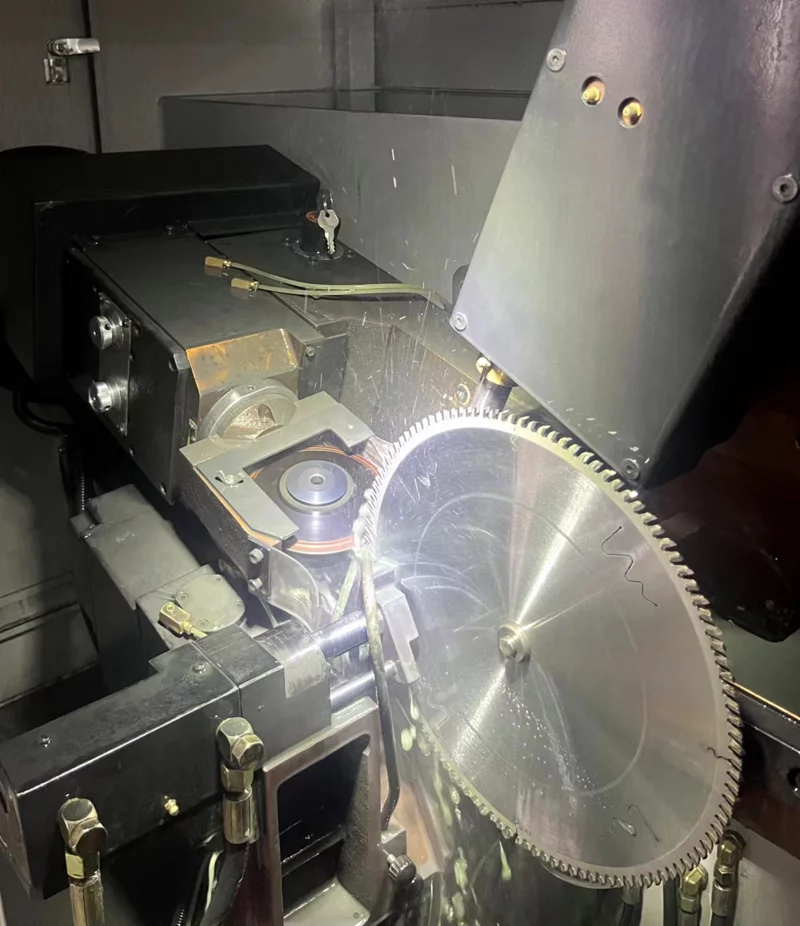

QH200 face and top grinding machine

The main characteristics of the light guide plate cutting saw blade include:

Firstly, high hardness is one of the important features of the light guide plate cutting saw blade. To maintain the sharpness of the cutting edge during long-term use, the blade is usually made of high-hardness materials. This effectively improves cutting efficiency and precision, ensuring smooth and accurate edges of the light guide plate.

Secondly, wear resistance is another key feature of the light guide plate cutting saw blade. Since the light guide plate is often made of hard materials such as acrylic or polycarbonate, the saw blade must have excellent wear resistance. This can withstand long hours of cutting operations and avoid decreased cutting quality due to excessive wear.

In addition, cutting efficiency is an important consideration in the design of the light guide plate cutting saw blade. To improve production efficiency and reduce costs, the blade usually adopts a unique design structure, enabling fast and efficient cutting work. This not only enhances production efficiency but also meets the needs of large-scale production.

At the same time, cutting precision is also a core requirement for the light guide plate cutting saw blade. As the light guide plate requires precise dimensions and shapes, the saw blade must have high precision cutting capabilities. This ensures that the cut light guide plate complies with optical requirements, with smooth edges and no burrs, improving product quality and performance.

In summary, the characteristics of the light guide plate cutting saw blade include high hardness, wear resistance, cutting efficiency, and cutting precision. These characteristics make it an essential tool for manufacturing high-quality light guide plates and provide strong support for the development of related industries. By using the light guide plate cutting saw blade, manufacturers can easily achieve efficient and accurate cutting of light guide plates, further promoting technological advancements and product innovation in related industries.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.