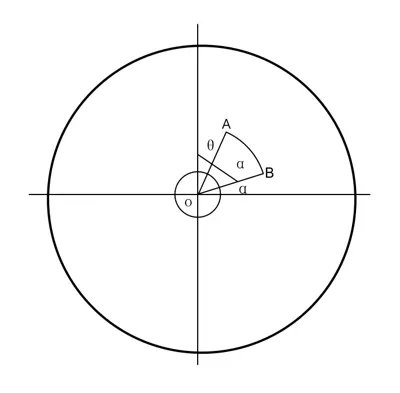

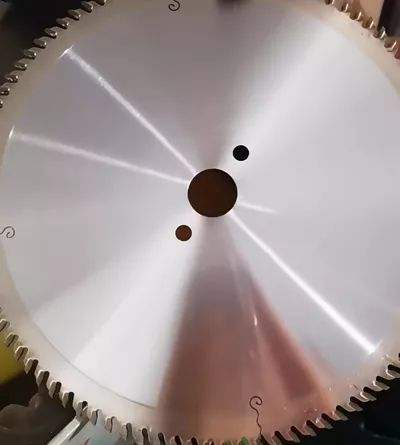

Brief explanation of the principle of stress correction of the circular saw tablet

Correction of stress in circular saw blade matrix is an important step in the manufacturing process of the saw blade, wh

Dive into our Product Knowledge Hub, where our expert sales team shares valuable insights on product knowledge and after-sales service, and more. Gain exclusive access to insider tips and resources to enhance your product ownership experience.

Correction of stress in circular saw blade matrix is an important step in the manufacturing process of the saw blade, wh

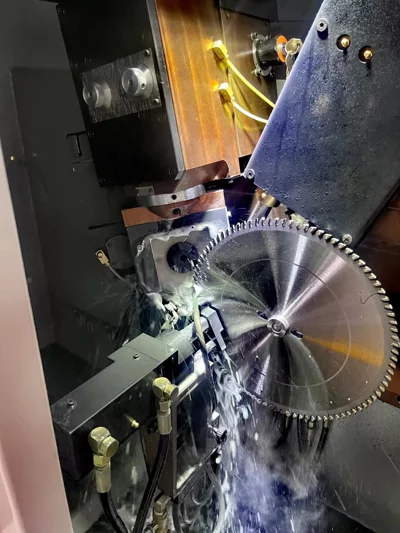

1. Grinding fluid characteristics: lubrication, cooling, degreasing, cleaning, rust prevention; it can effectively clean

1. Resin-bonded diamond grinding wheels have a weak bonding strength, which results in good self-sharpening performance

Factors that cannot be ignored in the grinding process of circular saw blades

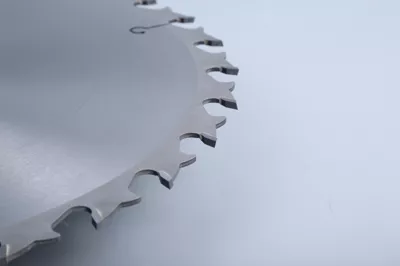

1. Alloy circular saw blade wear can be categorized into normal wear and abnormal wear. The tool undergoes intense frict

①Sandblasting corrosion: Usually, 36# silicon carbide sand is used for sandblasting at a distance of about 6kg pressure.

There has always been a saying in the machine tool industry that machine tools need to release stress, and the higher th

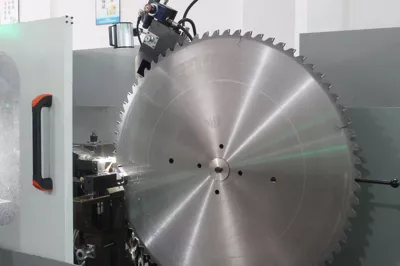

Aluminum alloy saw blades are used for cutting, sawing, milling, and grooving aluminum alloy materials. They are hard al