Brief explanation of the principle of stress correction of the circular saw tablet

Correction of stress in circular saw blade matrix is an important step in the manufacturing process of the saw blade, which can determine the stability and quality of the final cutting. Therefore, it is important to understand the basic principles of stress correction, which can help us have more reference data when choosing a saw blade and improve the inspection of saw blade quality.

A. Balanced matrix correction principle:

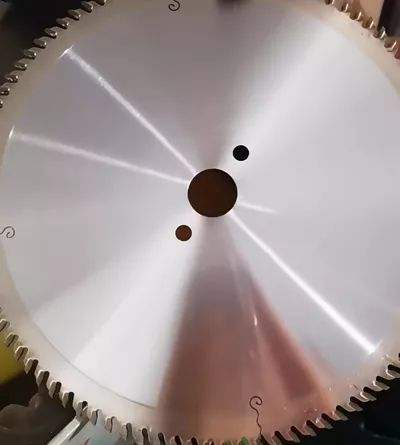

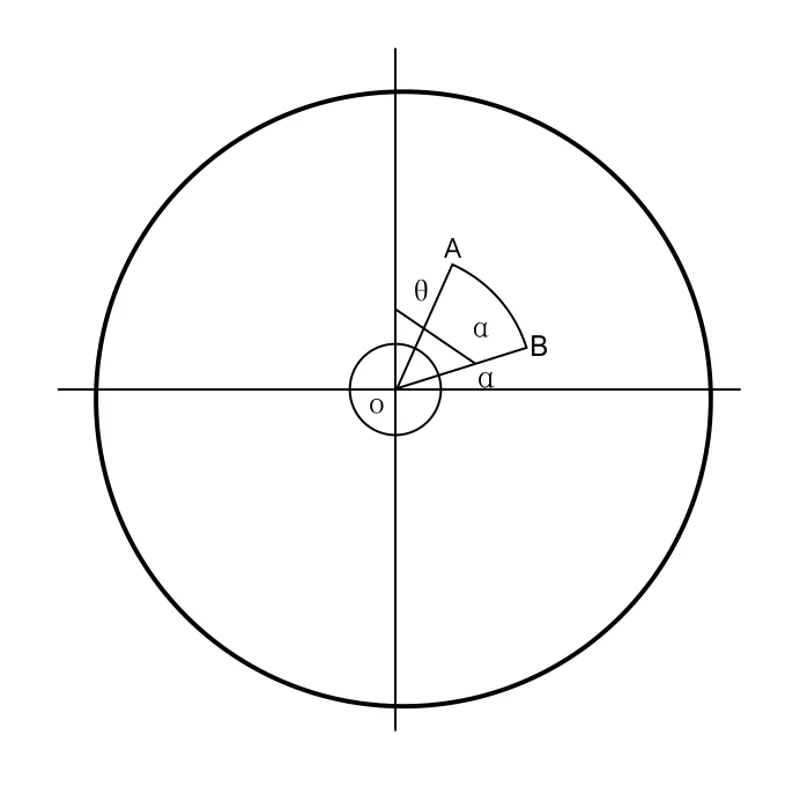

In general, the thickness-to-diameter ratio of the matrix of a saw blade is very small, especially for matrices below 1500, the difference in thickness-to-diameter ratio is within 1%, as shown in the figure below:

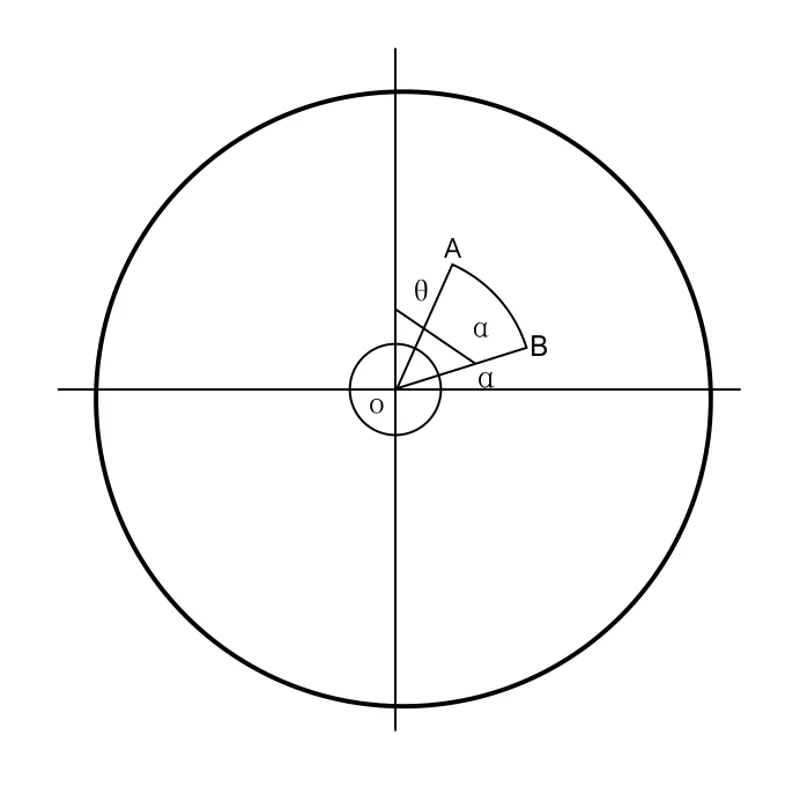

The positions of point A and point B on the matrix of the circular saw blade: Assuming that the arc length between point A and point B is aX, it can be judged that the size of this saw blade is balanced. However, if all the sizes on the matrix remain in a balanced position, it can be theoretically determined that the positional error value of the matrix of this saw blade is zero (only theoretically).

In some cases, there may be situations where the local numerical value of the circular saw blade matrix is greater than or less than X a, which will cause the loss of size balance in the matrix and lead to positional errors. In severe cases, it may exceed the specified limit of positional error, which will cause noticeable damage to the saw blade. Therefore, measures must be taken to make the size value of this local area close to or equal to X a, which can partially restore the balance of the matrix and achieve the effect of correcting the positional error.

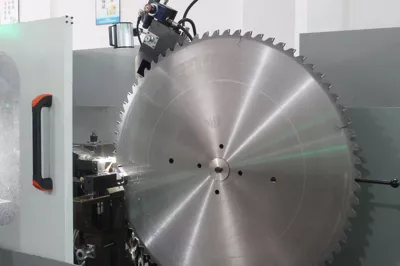

DY550 Saw blade stress point machine

B. Cold correction matrix principle:

By applying external force, a certain part of the matrix of the circular saw blade undergoes plastic deformation, resulting in the extension of the size of this part. The purpose is to make the size of this part close to a balanced state, reduce internal stress, and thus achieve the purpose of correcting the matrix.

C. Hot correction matrix principle:

By using artificial factors, a certain part of the matrix of the circular saw blade is rapidly heated and rapidly cooled, causing thermal plastic deformation of this part and resulting in size contraction during cooling (principle of thermal expansion and contraction). The ultimate goal is to make the size of this part close to or equal to the balanced state, reduce internal stress, and thus achieve the correction result of the circular saw blade matrix.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.