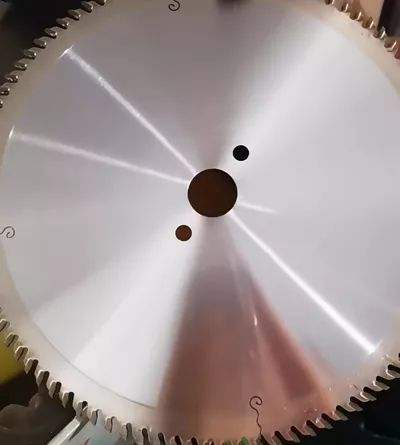

A multi-blade saw refers to the use of multiple saw blades installed together, usually using alloy saw blades.

1. Multi-saw blades are suitable for longitudinal cutting of solid wood, improving efficiency when used in groups. They provide good cutting results and are durable.

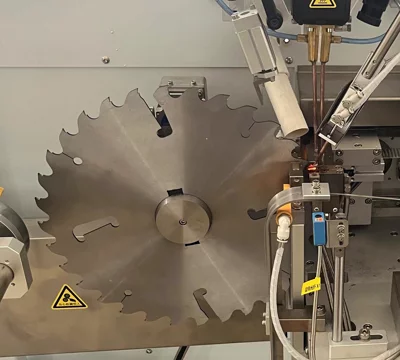

JX350 Face and top grinding machine(Robotic arm)

2. The outer diameter of multi-saw blades depends on the installation limits of the machine and the thickness of the cutting material. Small diameter blades are around 110mm, while larger diameter blades can reach 450mm or more. Some blades need to be installed simultaneously in the vertical or horizontal direction to achieve greater cutting thickness without increasing the blade diameter and reducing blade costs.

3. To reduce machine resistance, increase blade durability, and minimize noise, multi-saw blades are generally designed with fewer teeth. The outer diameter of 110-180mm blades usually has around 12-30 teeth, and for blades above 200mm, it is typically around 30-40 teeth. However, some machines with higher power or manufacturers emphasizing cutting performance may have designs with around 50 teeth.

4. The ideal thickness of multi-saw blades is generally thinner, as the sawing gap is a form of consumption. The material of the alloy blade matrix and the manufacturing process determine the blade thickness. If the thickness is too thin, the blade is prone to shaking during operation, which affects cutting efficiency.

5. The aperture of multi-saw blades depends on the requirements of the machine. Since multiple blades are installed together to ensure stability, the aperture is generally larger than that of conventional blades. In most cases, a special flange is also added to increase stability, along with the design of a keyway for easy addition of cooling agents. The aperture of blades with an outer diameter of 110-200mm is usually between 35-40, while for blades with an outer diameter of 230-300mm, the aperture is between 40-70. Blades with a diameter above 300mm generally have an aperture below 50mm.

6. The teeth of multi-saw blades are generally designed with alternating left and right teeth, while some small diameter blades may have a flat tooth design.

7. Multi-saw blades are usually coated after welding and grinding to prolong their lifespan. However, the main purpose of the coating is to improve the appearance of the blade, especially for multi-saw blades with scrapers. Due to the welding process, there are obvious welding marks on the scraper, so coating is applied for aesthetic purposes.

8. Multi-saw blades with scrapers have hard alloy welding on the blade matrix, collectively referred to as scrapers.

Scrapers are generally divided into inner scrapers, outer scrapers, and tooth scrapers. Inner scrapers are commonly used for cutting hardwood, outer scrapers for cutting wet wood, and tooth scrapers for trimming or edge sealing. However, this cannot be generalized for all cases.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.