Guide for the use of woodworking precision panel saws

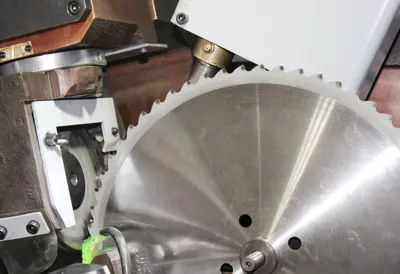

1. Before starting the machine, please clean the sliding table saw and the area around the workbench to ensure a neat working environment. Check if the saw blade is held perpendicularly, as this is an important step to ensure cutting accuracy.

When cutting large pieces of wood, place the wood steadily on the push table, aligning it with the reference stopper. Adjust the positioning stopper to secure the wood firmly. Then, turn on the power switch and control the feed rate of the feeder. Maintain a steady and moderate speed to avoid excessive or rapid operation.

Operators should wear masks and noise-reducing ear muffs to ensure safety and comfort during the work process. Also, do not wear gloves or loose clothing, and tie long hair to prevent accidental entanglement with the machine.

Do not directly touch the wood near the saw blade when it is rotating. If you need to move the wood, use another long piece of wood to push it to avoid injury.

2. When cutting small-sized wood, move the push table to a position that does not hinder operation. Adjust the distance from the fence to ensure cutting accuracy. Turn on the power switch and feed at a constant speed.

After cutting the wood in a short period of time, use a push stick to push the remaining wood towards the saw blade. This ensures the accurate positioning of the remaining wood for further cutting and slotting as needed. Using a push stick significantly reduces the possibility of accidents.

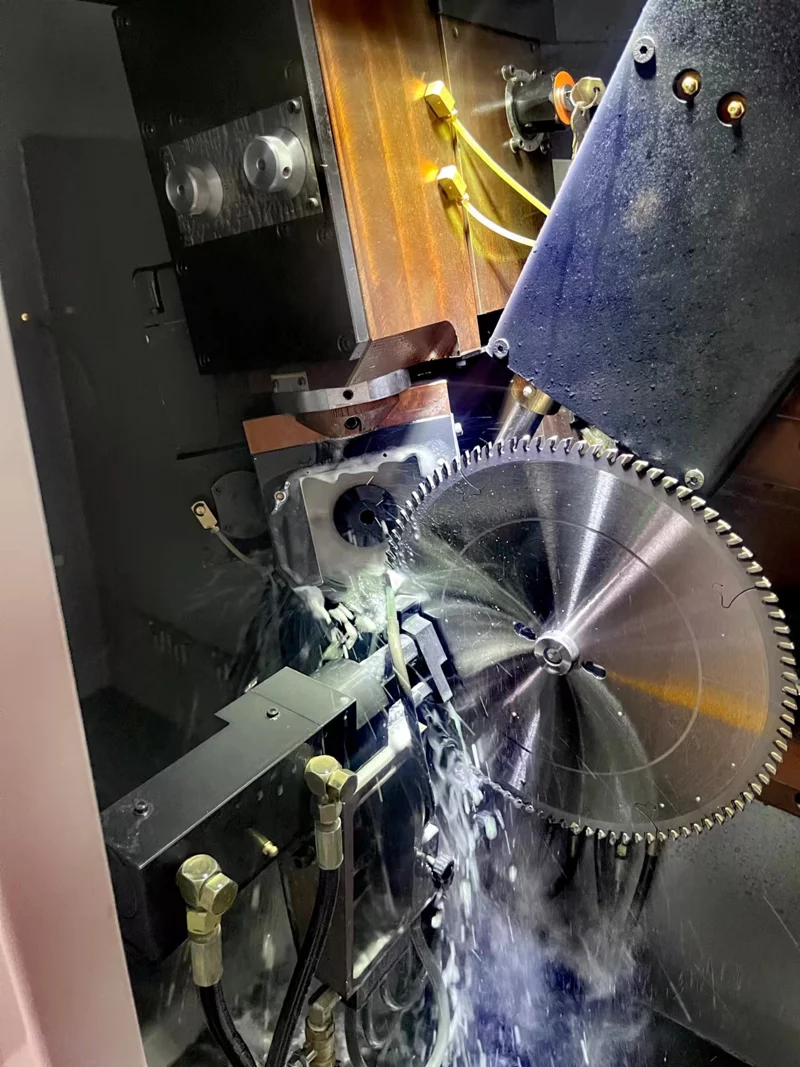

3. When the cut surface is rough or has a strange odor, please turn off the machine before inspecting and repairing. This may be a sign of machine failure or material issues that need further investigation and handling.

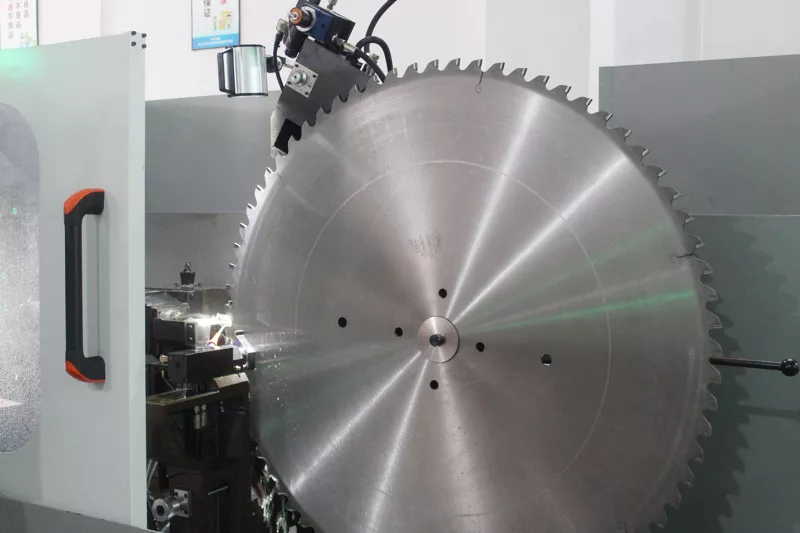

4. The chip removal trough and sound listening device of the precision panel saw should be regularly cleaned and maintained to ensure smooth operation. Especially for precision panel saws used for dry cutting, long continuous cutting should be avoided to prevent excessive wear or damage to the saw blade. If using a water-cutting wet blade, ensure that there is no electrical leakage.

QH200 face and top grinding machine

5. When cutting aluminum alloys and other metals, use specialized cooling and lubricating fluids to prevent the saw blade from overheating or getting stuck, thus ensuring cutting quality.

6. When using a precision panel saw for woodworking, the workpiece should be securely fixed, and the profiles should be positioned strictly according to the cutting direction. The feed should be smooth and powerful, avoiding side pressure or curved cutting, and preventing the saw blade from making impact contact with the workpiece to avoid blade damage or the workpiece flying out and causing safety accidents. During the start or end of the cutting, avoid excessive feed to prevent tooth breakage or damage to the precision panel saw blade.

7. If abnormal noises or vibrations are heard or felt during use, stop the equipment immediately and check for faults for repair. This may be a sign of machine failure or potential safety hazards, and timely action can prevent accidents from occurring.

Please follow the above guidelines when operating the woodworking precision panel saw to ensure safety and efficiency during the work process. If you have any questions or need further guidance, refer to the product manual or contact a professional.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.