Knowledge of Choosing T.C.T Circular Saw Blades

A. Basis for blade selection

Classified according to the material properties being cut

1. Solid wood: categorized into cross-cutting and rip-cutting.

Cross-cutting requires cutting through the wood fibers, requiring a smooth cut surface without knife marks or burrs. For this purpose, a 10-inch or 12-inch blade with 60 to 120 teeth is recommended, with more teeth used for thinner materials. The feeding speed should also be correspondingly slower. For rip-cutting, fewer teeth are needed, allowing for faster feeding speed. However, high requirements for chip removal mean that a 10-inch or 12-inch blade with 24 to 40 teeth is preferred. For cutting materials with many knots, a blade with raker teeth is recommended.

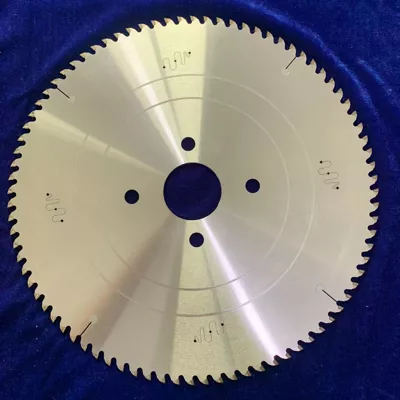

2. Man-made board: MDF, particle board, plywood

When cutting, one must consider cutting force and chip removal. For man-made boards, a 10-inch or 12-inch blade with 60 to 96 teeth is recommended.

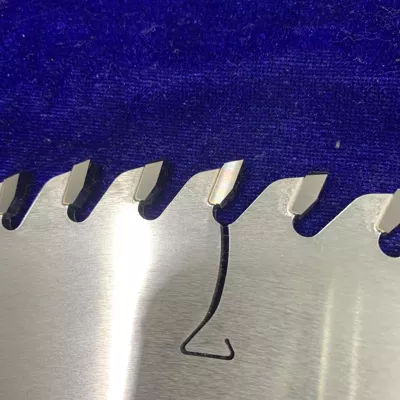

3. Common uses for two different tooth profiles:

(L&R teeth) Primarily used for cross-cutting and rip-cutting solid wood, laminated MDF, and plastics, among others.

(TCG teeth) Mainly used for hard double-faced laminated boards and non-ferrous metals.

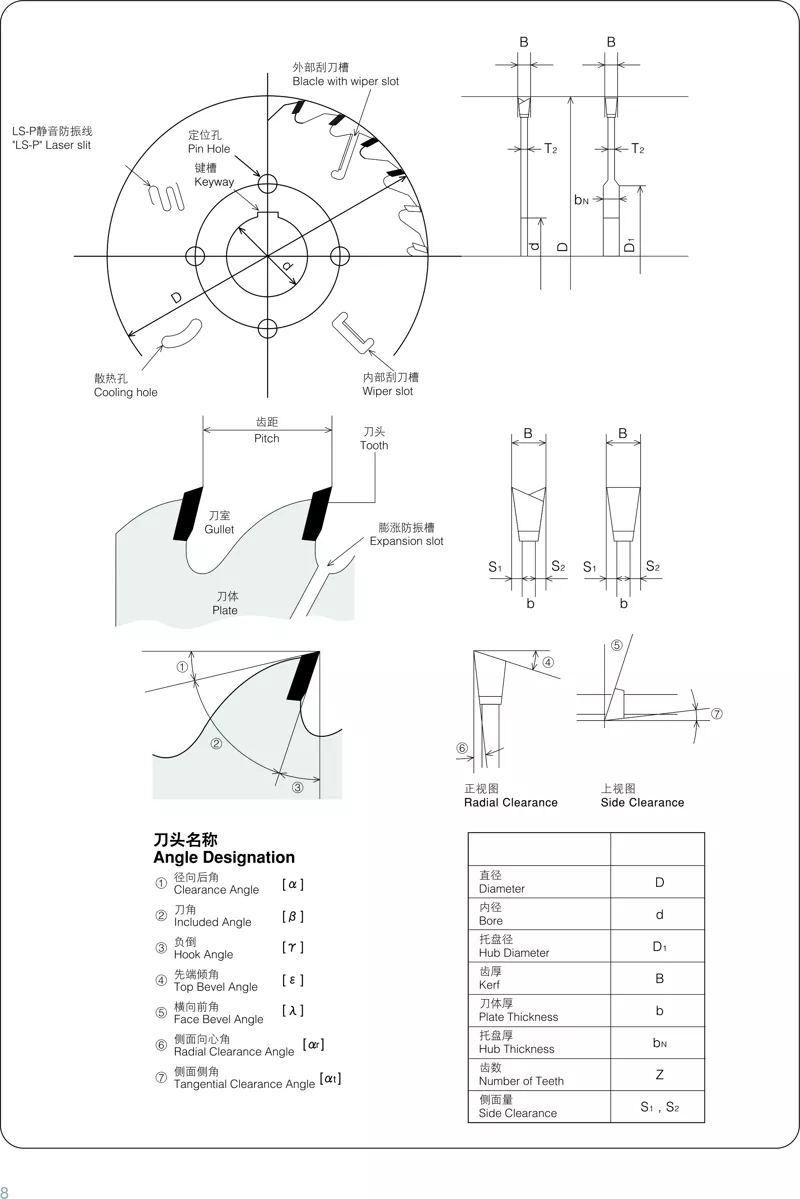

Basic blade data:

① Machine spindle speed,

② Workpiece thickness and material,

③ Blade outer diameter and aperture (shaft diameter) – all of these parameters can be found on the blade.

Remember: The spindle speed must never exceed the maximum speed of the blade for safety reasons. (I have seen many people use a blade on a vertical milling machine, which generally has a higher speed than the maximum blade speed – this is extremely dangerous.)

Selection basis: Calculate based on the spindle speed and intended matching blade outer diameter. Cutting speed: V = π x outer diameter D x spindle speed N / 60 (m/s). A reasonable cutting speed is generally between 60-90 m/s.

Specific recommendations:

Material Cutting Speed

Softwood 60-90 m/s

Hardwood 50-70 m/s

Particle board, plywood 60-80 m/s

Excessively high cutting speed leads to large machine tool vibration, loud noise, reduced blade stability, decreased processing quality, and reduced production efficiency. Similarly, with the same feeding speed, increasing the cutting amount per tooth affects processing quality and the lifespan of the blade. As blade diameter D and spindle speed N have a power function relationship, in actual application, it is more cost-effective to reasonably increase the speed and decrease the blade diameter.

DM100 face and top grinding machine

automatic saw blade sharpening machine

B. Correct usage:

To achieve the best performance of the blade, it must be used strictly according to specifications.

1. Blades of different specifications and uses have different designed cutting angles and base forms. They should be used accordingly whenever possible.

2. The spindle of the equipment and the size and positional accuracy of the clamping plate have a significant impact on the performance. It is necessary to check and adjust before installing the blade. In particular, factors causing displacement and slipping due to the clamping plate's contact with the blade must be eliminated.

3. Pay attention to the working condition of the blade at all times. If any abnormalities occur, such as vibration, noise, or material deviation during machining, it must be promptly stopped for adjustment and maintenance, ensuring the peak performance of the blade.

4. When sharpening the blade, the original angles must not be changed, and care should be taken to avoid sudden heating or cooling of the cutting edge. It is best to seek professional sharpening.

5. Blades that are not currently in use should be hung vertically and not placed flat for long periods, and they should not have any objects stacked on top of them. The cutting edge should be protected and not allowed to collide with any objects.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.