Common problems with saw blades and their solutions

When using saw blades, we may encounter various problems such as being not durable, teeth being broken, or cracks in the matrix. So how should we deal with it? Should we discard and replace it or recycle it? Clearly, what we need to do is maximize the utilization of saw blades to generate greater benefits for the company!

Analysis and solutions for the problem of saw blades being not durable:

1. Equipment problems

A. Problem analysis

If the saw blade is not durable, there are generally problems with the equipment or the saw blade itself. First of all, we should carefully check the equipment (such as whether the installation is in place, whether the model matches, whether the equipment parts are aging, etc.). If there is no problem with the equipment, then the quality of the saw blade itself is the issue.

B. Problem handling

1) Not being durable due to installation problems

When installing the saw blade, it is essential to have professionals operate it, paying attention to the direction (teeth facing right) and checking whether all screws are tightened.

2) Coordination performance between various components

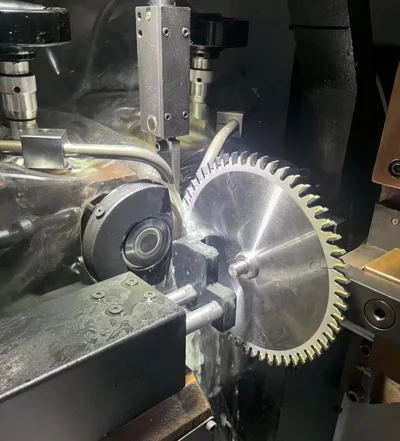

After installing the saw blade, it is necessary to perform a trial cut to ensure that there are no problems. If there is any deviation, vibration, or unstable sound during cutting, it must be rectified in a timely manner.

3) Aging or instability of equipment components

Check whether the equipment components are aging or operating unstably, as this is also one of the important reasons for the saw blade not being durable. A quick way to check is to judge by sound. For example, if there are abnormal noises during equipment operation or if the sound produced by the saw blade is unstable, it indicates equipment instability or aging symptoms.

4) Cleaning and hygiene

After working, the equipment will produce a large amount of iron filings. It is important to clean them up in a timely manner. If not cleaned for a long time, the iron filings may enter the internal parts of the equipment or the saw blade, indirectly causing equipment instability or teeth breaking. Therefore, it is necessary to clean before use.

2. Quality problems of the saw blade itself

A. Problem analysis

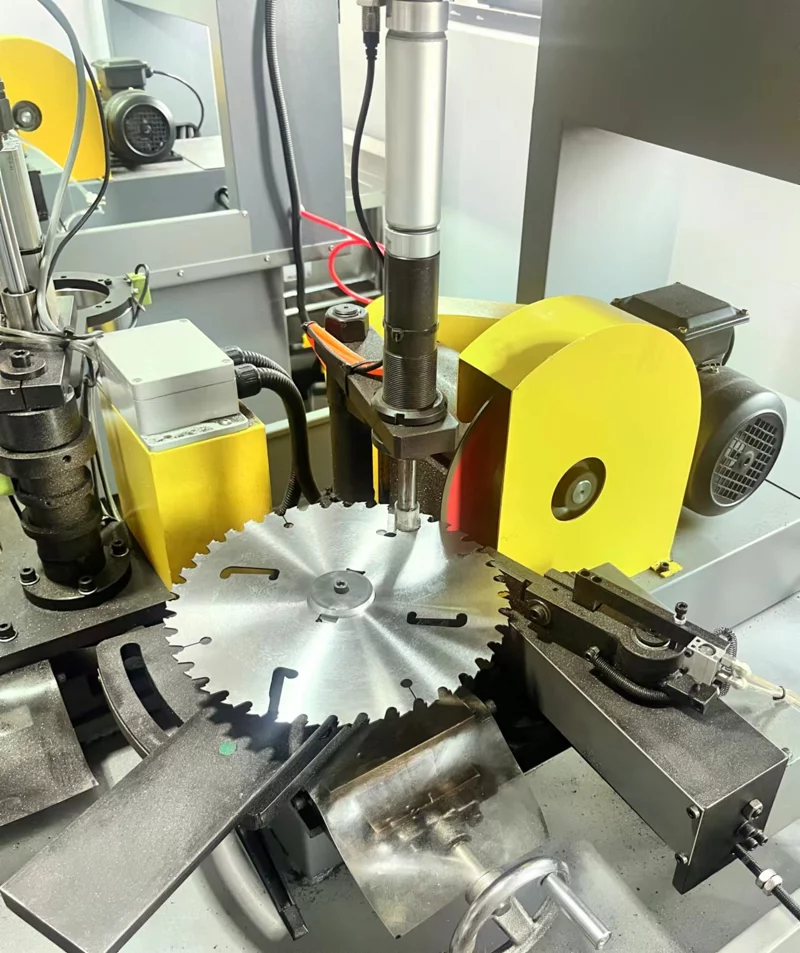

If there is no problem with the equipment, the reason for the saw blade not being durable is generally due to quality issues of the saw blade itself, such as poor material used for making the saw blade or improper production process. Inferior saw blades can also affect compatibility with the equipment.

B. Problem handling

1) Poor material used for the saw blade

The poor material used for the saw blade will greatly affect its compatibility with the equipment, leading to unstable cutting and other problems. In severe cases, it can cause teeth breaking or fracture of the saw blade.

When selecting saw blades, users must consider various factors and not blindly choose based on price.

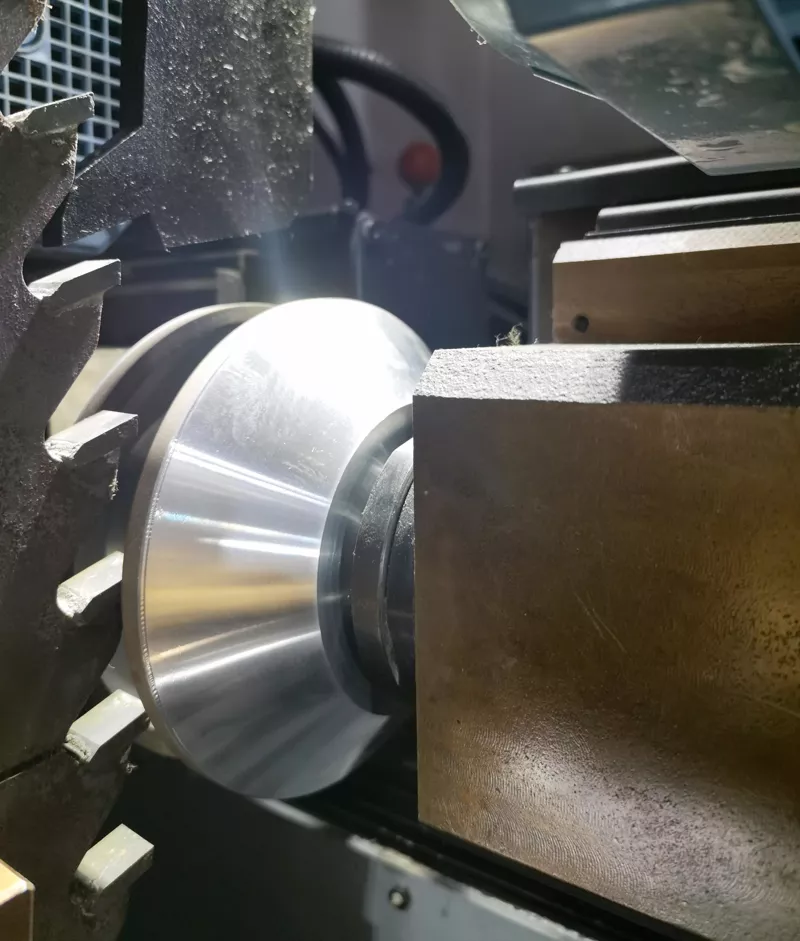

2) Improper production process

After purchasing the saw blade, users must perform inspections and other work because no supplier can guarantee the integrity of the goods 100%. Factors such as bumps during transportation can cause uncertainties after receiving the goods. Inspecting the saw blade upon receipt is responsible for oneself and also supervises the supplier.

3. Other common reasons for the saw blade being not durable

In addition to the reasons mentioned above, there are other factors such as whether the saw blade parameters correspond to the material and equipment, whether the cutting oil meets the regulations, whether the wire brush installation is correct, and whether the use is normal, all of which will affect the use of the saw blade.

Saw blades guarantee the cutting cost and the quality of the workpiece in the equipment. When using them, strict control and corresponding maintenance and care measures must be taken.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.