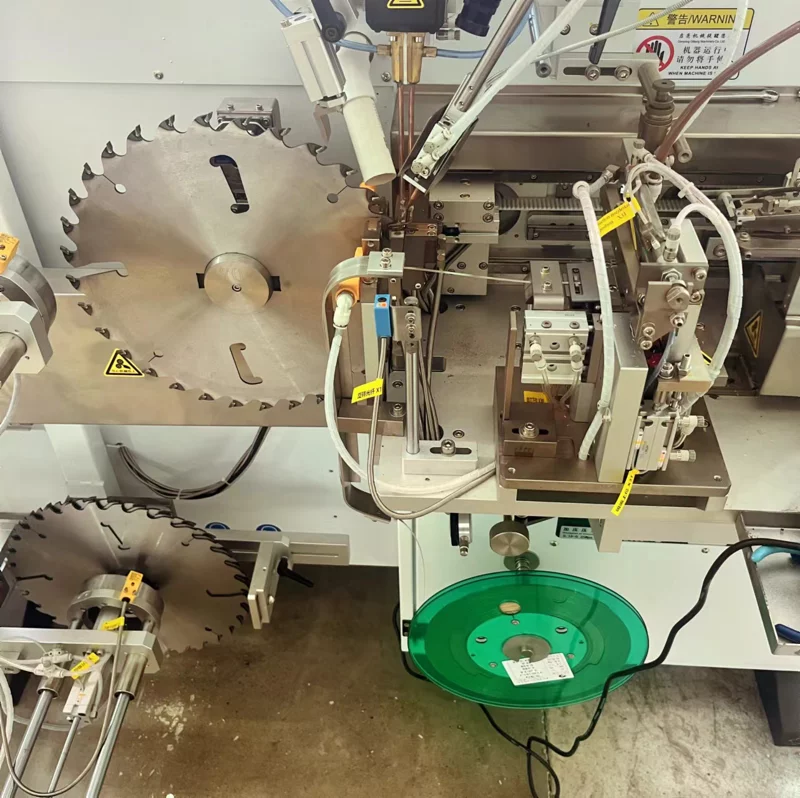

Carbide circular saw blade production process- Saw blade welding teeth 03

1 The length of the solder joint should be 1-2 mm shorter than the length of the alloy, and it should not protrude too much, covering the entire alloy. (Width < steel plate thickness 1-2mm)

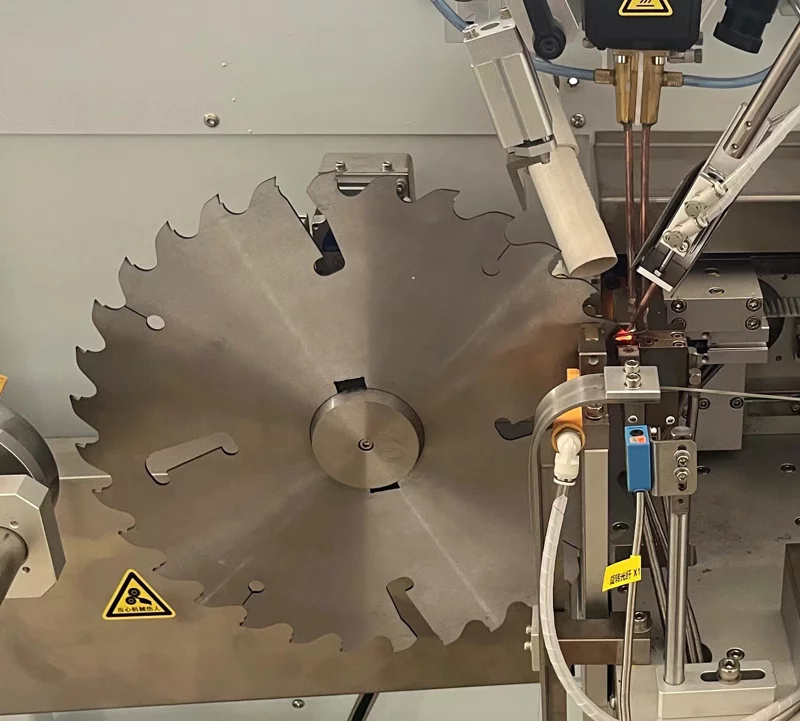

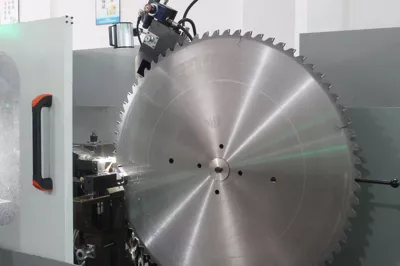

2 First weld 1-2 teeth and measure the hardness and welding angle of the tooth back. There should be no virtual welding, bubbles, or misalignment. If any problems are found, they should be adjusted in a timely manner. (Common problems: ① Virtual welding: Check if the angle is not correct and whether the alloy is on the same horizontal line as the tooth seat, and whether the weight of the welding pad or wire matches. ② Welding is not in place, the welding pad does not melt, and there is a gap between the bottom of the alloy and the tooth seat: Check if the tooth seat has concave and convex shapes, and whether the distance between the heating ring and the alloy is within the standard range. Generally, both sides are within the range of (1-2 mm), and the temperature is generally 630/700 ℃.), Heat the melting point of the solder pad to determine the welding time

3. Welding angle tolerance: ± 1 ℃, welding left and right alignment tolerance: ± 0.05mm. (Symmetric tolerance of the thin film on both sides: ± 0.03mm).

4 Teeth should be welded to prevent local overheating and cracking.

5 Adjust the appropriate tempering time based on the size of the alloy and the hardness and size of the tooth seat. The hardness of the tooth back is required to be between 35-42 degrees (for thin films, it is between 40-46 degrees), and the tolerance point for tooth back hardness is generally within 5 degrees as the standard. When the hardness point exceeds the standard range, it is necessary to promptly check the tempering position of the induction ring and make adjustments.

6 Each welded saw blade must undergo a destructive test. Place a wooden board flat, pick up the saw blade vertically, and tap the board vertically downwards towards the top of the teeth to see if the alloy has fallen off.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.