Short lifespan of aluminum alloy saw blades These methods to extend lifespan are important for cost reduction

The importance of aluminum alloy saw blades in the aluminum processing field is self-evident. For those who have been in this industry for a long time, the quality of the saw blades is undoubtedly a key element in the production process. It is like a brush to a painter, directly affecting the final products of the company.

Despite the rapid development of manufacturing and processing technology for saw blades, as a consumable, saw blades are always a problem that many companies cannot ignore. Why would this thin saw blade become a headache for companies? The answer primarily lies in its quality, price, and lifespan.

First is the price, which is directly related to the operating cost of the company. Then there is the quality, which is like a ruler measuring the quality of the products. Finally, there is the lifespan, which affects the production output of the company per unit of time. Because of this, companies are always cautious when choosing aluminum alloy saw blades, and they won't make decisions without thorough investigation.

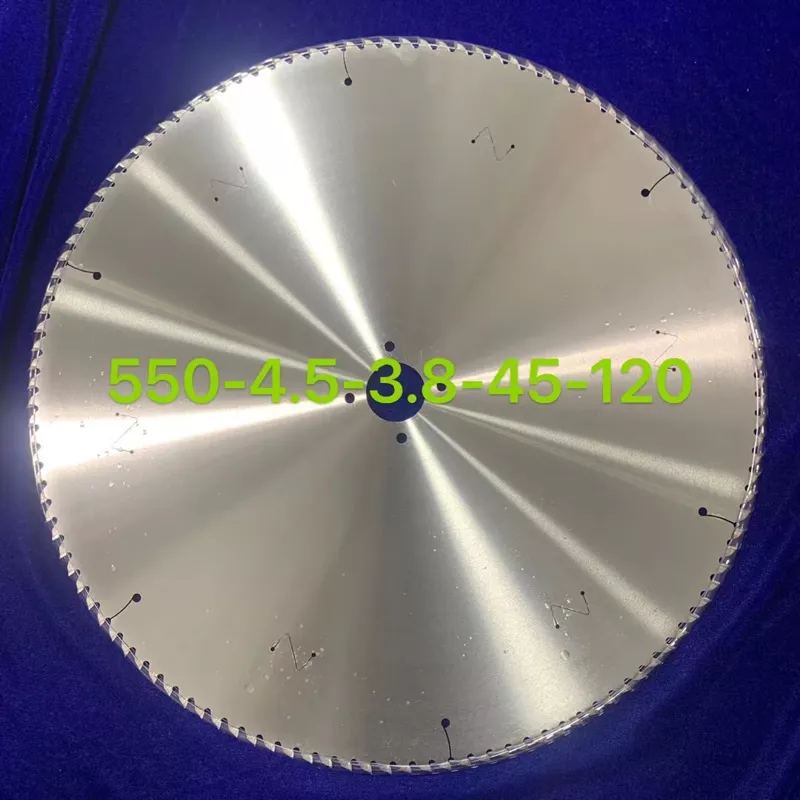

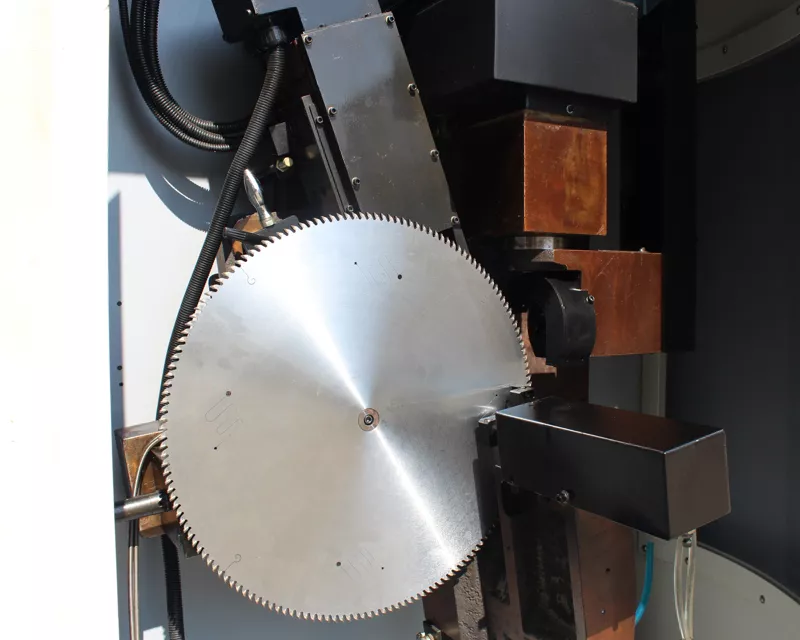

DM100 face and top grinding machine

Once the saw blades are put into production, their lifespan becomes the primary concern of the company. When the quality of the saw blades is guaranteed, their lifespan directly determines the cost-effectiveness of these aluminum alloy saw blades. To extend the lifespan of saw blades, we must thoroughly study various factors that affect their lifespan. Generally, these factors include the following:

Key factors that affect saw blade lifespan:

Selection of raw materials for saw blades: Each material has its unique properties. Some materials have excellent thermal conductivity but poor wear resistance, while others have all-around performance but are relatively expensive. For aluminum profile processing companies, it is crucial to choose the appropriate saw blades according to their actual needs. For example, high-speed steel saw blades have strong capabilities in thermoplasticity and high-temperature resistance, and they have a longer lifespan but are more expensive. In comparison, saw blades made of carbon tool steel have a relatively shorter lifespan due to their metallic characteristics.

Friction and heat: When cutting aluminum profiles, saw blades generate significant friction and heat with the raw materials. Once the temperature exceeds the limit that the saw blades can bear, they may be damaged, leading to shortened lifespan.

Wisdom of cutting oil: To improve the lifespan of saw blades, cutting oil comes into play. Some forward-thinking companies have even integrated cutting oil into fully automatic aluminum cutting machines to further optimize the performance and lifespan of saw blades. Through a precision-designed micro-lubrication system, 0.05 milliliters of cutting oil is accurately sprayed onto the saw blades every second, which not only achieves effective lubrication and cooling but also significantly extends the lifespan of the saw blades. We must admit that besides these factors mentioned above, there are many other factors that can impact the lifespan of saw blades. For example, whether the employees' operations comply with standard procedures, whether there are any improper uses of the saw blades, all these potential factors can affect the lifespan of the saw blades.

As the ancient saying goes, "Know yourself and know your enemy, and you will never be defeated in a hundred battles." After understanding the factors that affect the lifespan of saw blades, we can take targeted measures from the source to ensure the durability of the saw blades.

How to extend the lifespan of saw blades?

Method 1: Optimize the selection of saw blades

As consumables, saw blades naturally have a limited lifespan. Even for internationally renowned brands, they cannot guarantee zero damage during continuous use. Therefore, for aluminum profile processing companies, it is crucial to choose a high-quality saw blade. It is wiser to be prepared beforehand than to remedy afterwards. To avoid adverse impacts on the production process due to low-quality saw blades, we should control the purchase of saw blades from the source and choose a high-quality and aftersales-guaranteed saw blade.

Method 2: Extend the lifespan of saw blades through resharpening

Imagine that the scissors in our home become blunt, we can restore their original sharpness and extend lifespan through simple resharpening. Similarly, for saw blades, we can also improve their lifespan through resharpening. Yes, you heard it right, saw blades can be resharpened.

When a company's saw blades become worn out and the teeth become dull due to long-term use, we can use a professional saw blade resharpening machine to restore them. After special resharpening, the saw blades can become sharp again, thereby extending their lifespan.

Generally, the lifespan of a saw blade in extreme use conditions is approximately 1 to 3 months. But through resharpening, the lifespan of the saw blade can be extended for at least another month. This not only reduces the cost of purchasing new saw blades for aluminum profile processing companies but also saves precious time for purchasing new saw blades, ensuring the continuity of the production process.

Seemingly insignificant saw blades, if we give them sufficient attention and take effective measures to extend their lifespan, it is undoubtedly

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.