Operation Procedure

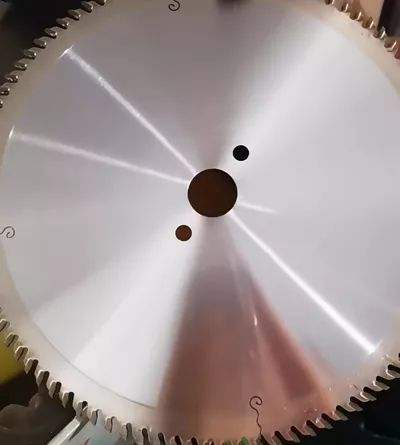

1. Choose the appropriate core sleeve based on the size of the saw blade hole and install it (the gap between the hole and the core sleeve complies with the tolerance fit standard).

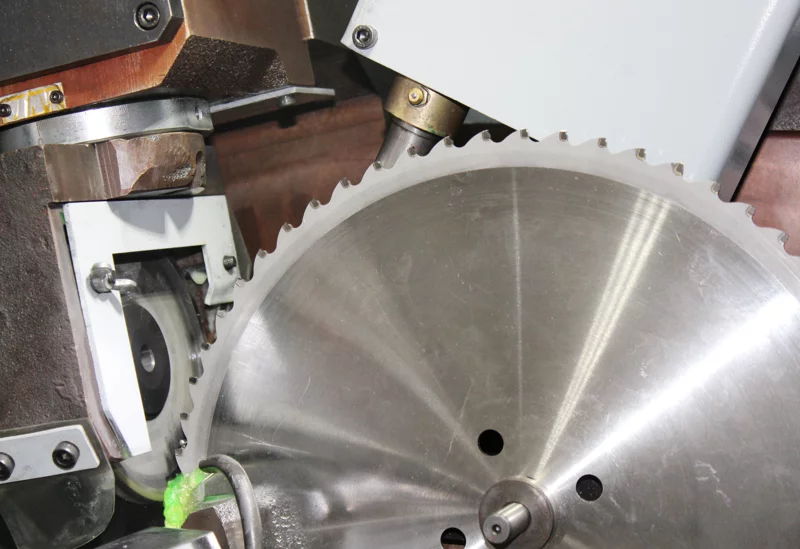

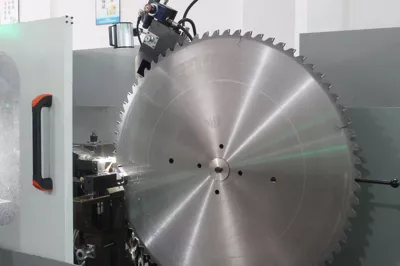

2. Place the saw blade on the flange, and place the dial indicator probe about 10mm below the tooth root of the saw blade.

3. Gently rotate the saw blade by hand, and judge the deformation position of the saw blade based on the reading of the dial indicator.

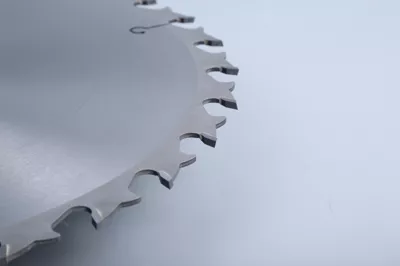

4. Once the position is found, take out the saw blade, and use a micrometer to find the bulge on the surface of the saw blade.

5. Hammer the bulge with appropriate force, repeatedly hammering until the bulge is flat.

6. For saw blades with offset, identify the lower side of the offset, then strike around the hole with a hammer, while measuring with a dial indicator, until both sides are parallel.

Process Requirements, Quality Control Requirements

1. The end jump of the saw blade should be within 0.03~0.04mm.

2. The flange must be clean.

3. When measuring, the dial indicator pointer should be at the zero position.

Maintenance Precautions

1. Clean the workstation before and after work.

2. Apply rust-proof oil to the unused saw blade core sleeve for storage.

3. Apply rust-proof oil to the flange and keep it clean.

4. Handle the micrometer and dial indicator with care.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.