Purchasing and Usage Considerations for Light Guide Panel Cutting Saw Blades

The light guide panel cutting saw blade is a tool specifically used for cutting light guide panels. For this special tool, the selection and usage of the saw blade need to be carefully considered to ensure optimal performance and efficient cutting. Below are several key considerations:

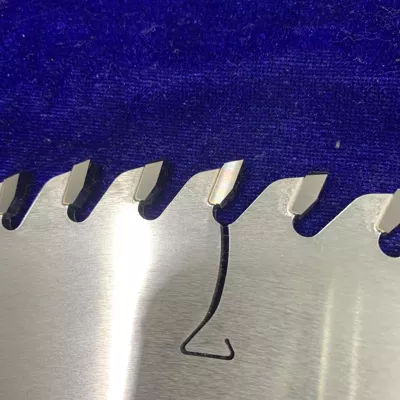

1. Saw blade material:

The material of the light guide panel cutting saw blade is an important factor determining its performance. Since light guide panels are typically made of materials like organic glass and polycarbonate, it is necessary to ensure that the saw blade can adapt to the characteristics of these materials when selecting the saw blade. High-quality light guide panel cutting saw blades are usually made of hard alloy or superhard materials to ensure high hardness and wear resistance. Such saw blades can maintain sharp and stable cutting effects during the cutting process, thereby improving cutting quality and efficiency.

2. Blade shape and size:

Light guide panels come in various shapes and sizes, so when selecting a light guide panel cutting saw blade, it is necessary to choose the appropriate blade shape and size based on specific cutting needs. Generally, larger diameter blades can provide higher cutting efficiency and are suitable for large-scale production needs. Smaller diameter blades are suitable for situations requiring fine cutting, ensuring the flatness and accuracy of the cutting edge.

3. Cutting speed and feed speed:

Cutting speed and feed speed are issues that need special attention when using light guide panel cutting saw blades. Excessive cutting speed may result in uneven cutting edges or cracks, affecting cutting quality. On the other hand, excessively slow cutting speed will affect work efficiency. Therefore, when using light guide panel cutting saw blades, it is necessary to reasonably control the cutting speed and feed speed based on the specific cutting material and saw blade type. During actual operation, parameters should be adjusted gradually to find the most suitable cutting conditions for achieving optimal cutting effects and work efficiency.

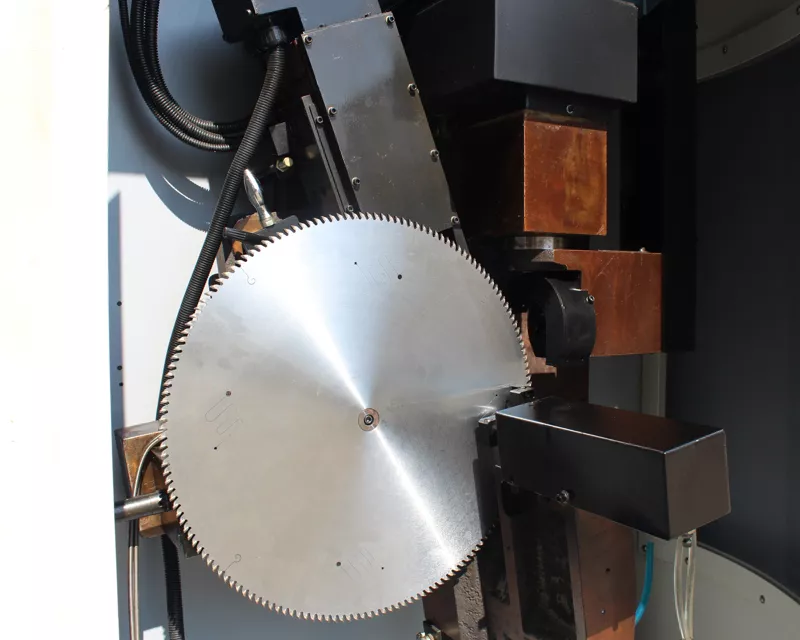

QH200 face and top grinding machine

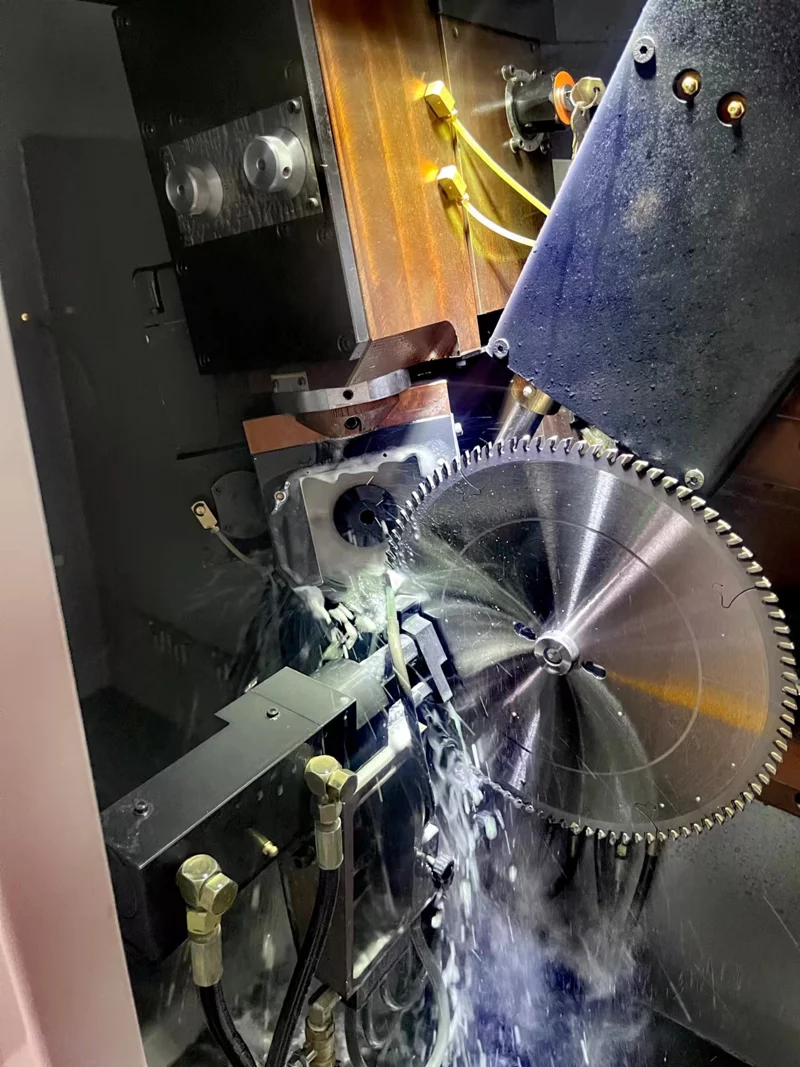

4. Cutting lubrication and cooling:

Due to the unique nature of light guide panel materials, high temperatures can be generated during the cutting process, requiring lubrication and cooling. Using the appropriate cutting fluid can reduce friction, reduce heat accumulation, and prolong the service life of the saw blade. During operation, it is important to ensure a continuous and uniform supply of lubricating fluid to maintain the optimal working condition of the saw blade. Additionally, regular inspections of the cooling system should be conducted to ensure its normal operation and prevent saw blade damage or a decrease in cutting quality due to overheating.

In conclusion, the selection and usage of light guide panel cutting saw blades require considering multiple factors. By carefully selecting the appropriate saw blade, controlling the usage parameters, and focusing on lubrication and cooling, it is possible to ensure that light guide panel cutting saw blades perform at their best in practical applications, improving cutting quality and efficiency.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.