Operation rules

1. Turn on the power switch and check the air pressure.

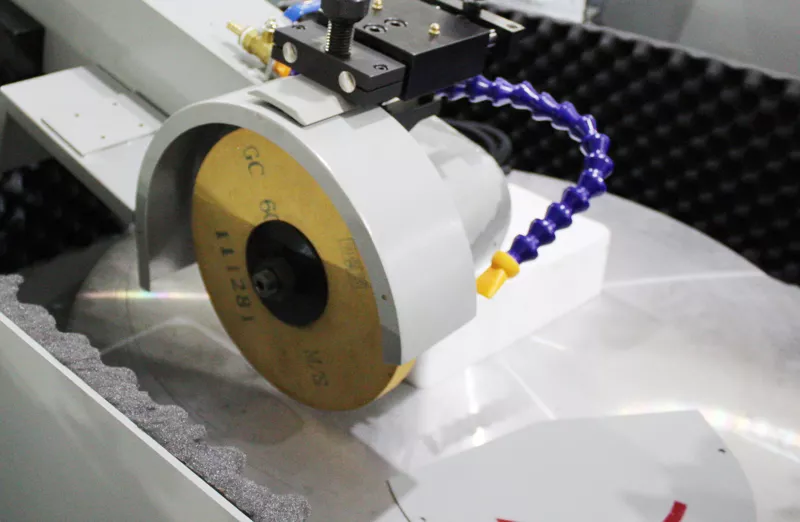

2. Start the grinding wheel and turntable to check if they are running properly.

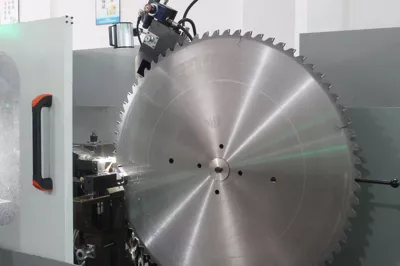

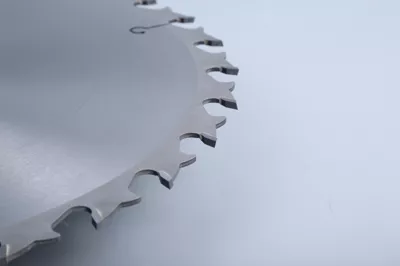

3. Select the appropriate core sleeve according to the inner hole of the saw blade (the gap between the inner hole and the core sleeve meets the tolerance fit standard, and the thickness of the core sleeve is half of the saw blade thickness).

4. Load the saw blade, adjust the throttle valve to achieve a suitable swinging speed (the smaller the grinding wheel, the greater the swinging speed should be).

5. Adjust the stroke for polishing the saw blade according to its size (note: the stroke of the polishing wheel refers to the distance from the sandblasting area of the saw blade to the inner hole is the polishing range), and lock the stroke.

6. Start the machine for trial polishing, check the smoothness and any patterns on the saw blade after polishing a piece. If it meets the requirements, adjust the polishing frequency to start polishing.

7. After polishing, use an air gun to blow dry the water and prepare for the next process.

Process requirements, quality control requirements

1. When the grinding head descends, it should be supported by hand to prevent damaging the saw blade.

2. There should be no obvious processing marks on the inner hole of the saw blade.

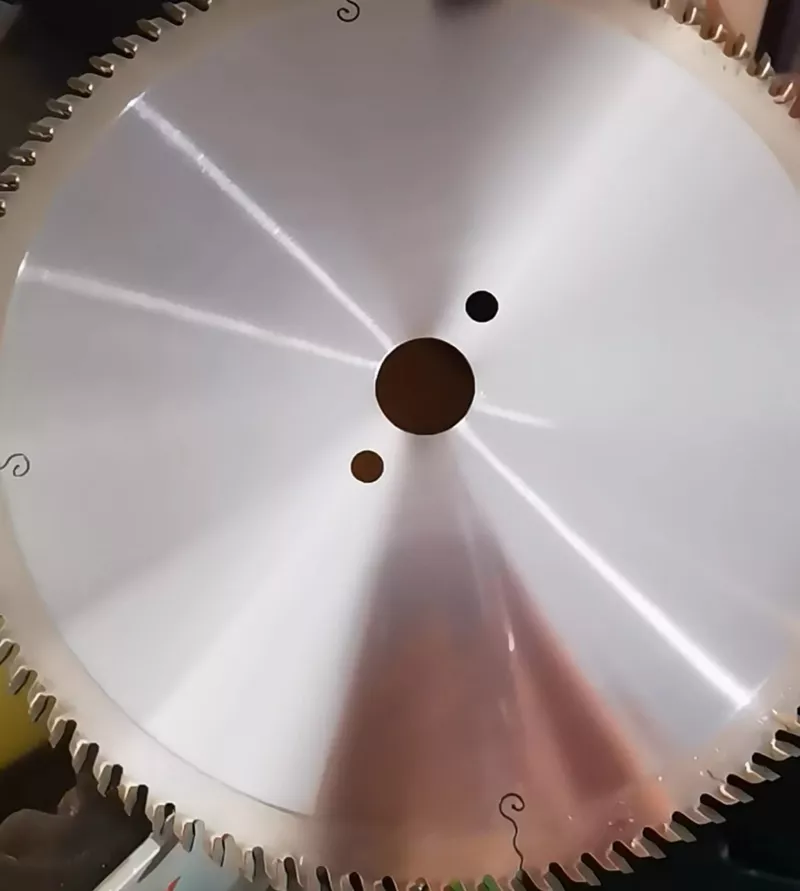

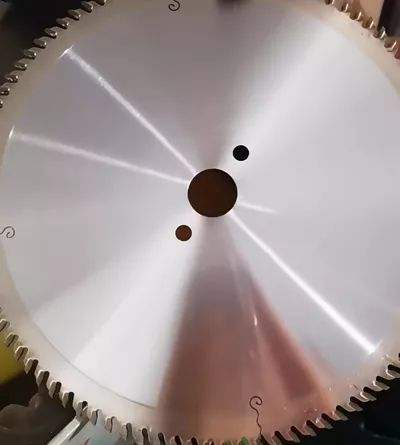

3. The surface of the saw blade should be as smooth as a mirror, without vibration marks. If vibration marks appear, check if the polishing wheel is vibrating or uneven, and promptly repair or adjust the polishing wheel.

4. If the inner and outer edges are not fully polished, check if the stroke is in place and if the thickness of the core sleeve exceeds that of the saw blade. The thickness of the core sleeve should generally be thinner than the saw blade. Also, check if the polishing wheel is tilted and adjust it promptly.

Maintenance precautions

1. Clean the equipment before leaving work.

2. If there is any abnormal noise during equipment operation, stop the machine immediately for inspection and repair before restarting.

3. Drain the water from the air triad components and top up the hydraulic oil if it is insufficient. (Note: Hydraulic oil in the triad components generally needs to be replenished every 10-15 days)

4. Check that the hydraulic oil level is not below the minimum level line, and top up the hydraulic oil immediately to bring it back within the normal range.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.