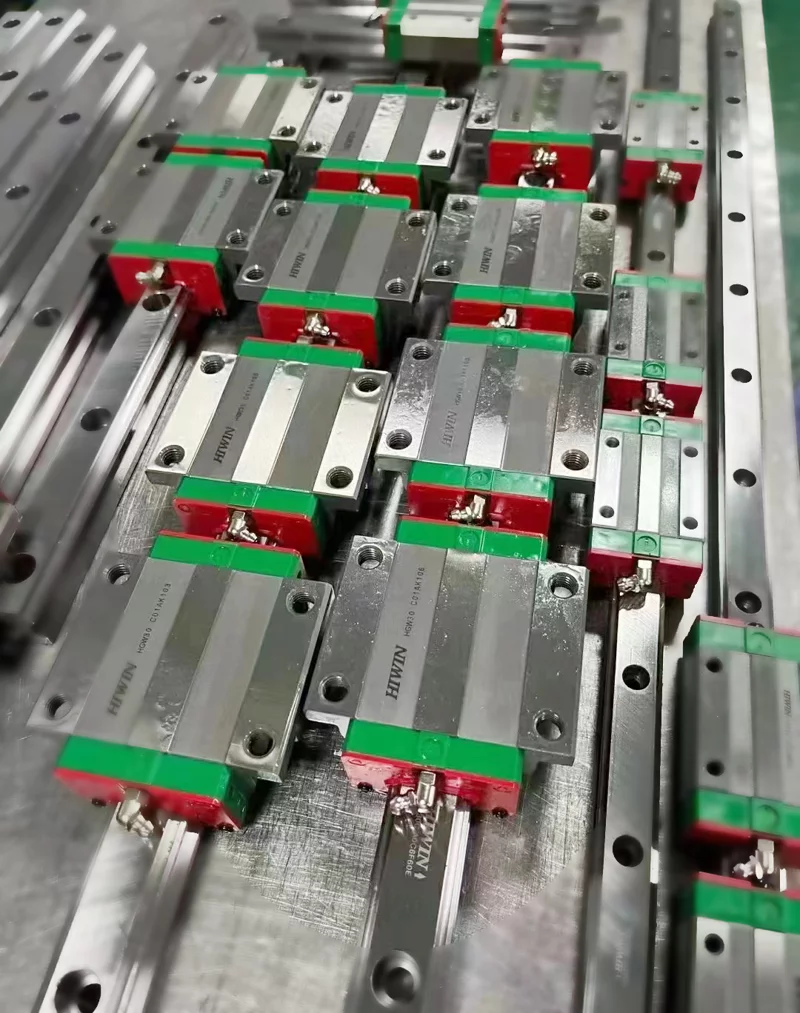

Needle roller guides and ball guides used in circular saw blade grinding equipment

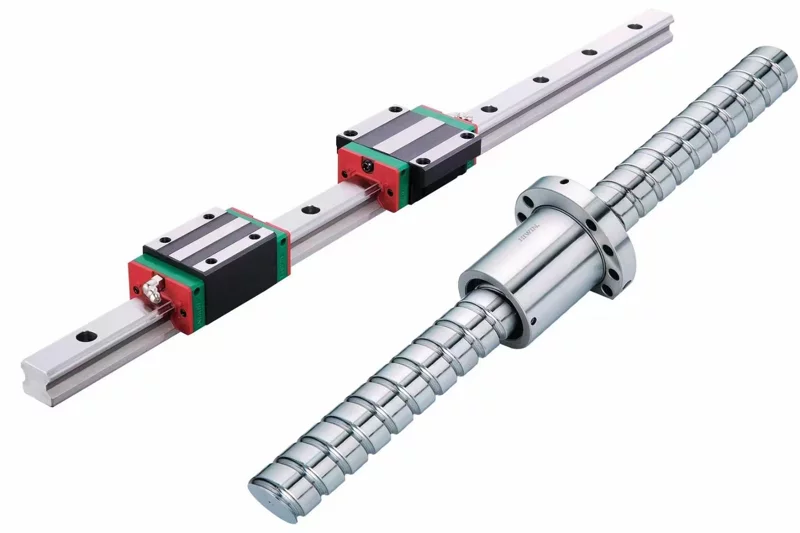

Lingbang Machinery's equipment, with its unique design and exquisite craftsmanship, has forged an unparalleled core mechanical structure. Within this core structure, the ingenious use of ball guideways and needle guideways has become the cornerstone of its stable operation. The design of these two types of guideways is based on a deep understanding and precise control of the characteristics of moving parts, ensuring precise and efficient motion of the equipment in various complex environments.

Needle Guideways:

**Design:**

Needle guideways use slender cylindrical needles as rolling elements, arranged at certain intervals between the guideway and the slider.

**Advantages:**

* **High Load Capacity:**

Needle guideways can withstand high radial and axial loads due to the small contact area between the needles and the guideway, providing substantial support.

* **High Rigidity:**

Due to the structural characteristics of needles, needle guideways exhibit high resistance to bending and twisting, suitable for applications requiring high precision and rigidity.

* **Good Thermal Stability:**

Needle guideways have low sensitivity to temperature changes, maintaining excellent performance even in high or low-temperature environments.

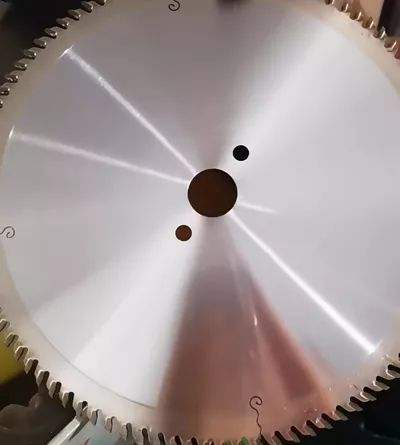

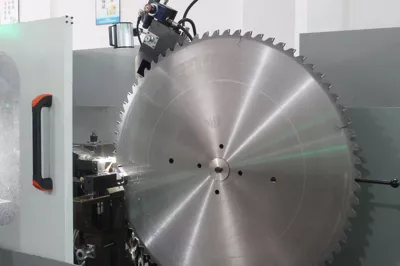

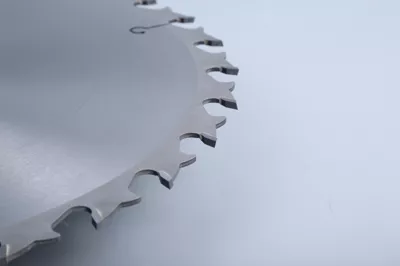

During the grinding of hard alloy circular saw blades, when the grinding wheel speed reaches 6000 revolutions per second, it is imperative to use a machine body material with high load capacity and rigidity to ensure the processing accuracy of the alloy circular saw blade while maintaining overall grinding stability.

Ball Guideways:

**Design:**

Ball guideways use spherical balls as rolling elements, placed in grooves or tracks between the guideway and the slider.

**Advantages:**

* **Smooth Motion:**

Ball guideways offer smoother motion as the contact area between the balls and the guideway is larger, providing better smoothness and stability.

* **Low Friction:**

The friction coefficient between the balls and the guideway is small, resulting in lower friction resistance and energy consumption.

* **Longevity:**

Ball guideways exhibit good wear resistance, maintaining a longer lifespan with relatively simple maintenance.

In the operation of the alloy circular saw blade grinding equipment, maintaining overall smooth motion of the moving parts and reducing the resonance caused by friction force on the grinding of alloy circular saw blades, the importance of ball guideways becomes particularly evident.

In summary, needle guideways and ball guideways each have their unique advantages and applications. Needle guideways are suitable for applications requiring high load-bearing capacity and rigidity, while ball guideways are more suitable for scenarios requiring smooth motion, low friction, and long life. When selecting, comprehensive considerations should be made based on specific requirements of mechanical equipment, working conditions, and precision demands.

Welcome to browse more about circular saw blade grinding equipment page, please click...

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.