Operating Procedures

1. Turn on the power and check if everything is running properly.

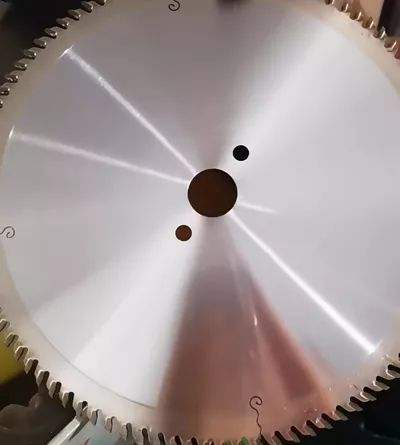

2. Select the appropriate core sleeve based on the hole in the saw blade (the gap between the hole and the core sleeve meets the tolerance fit standard).

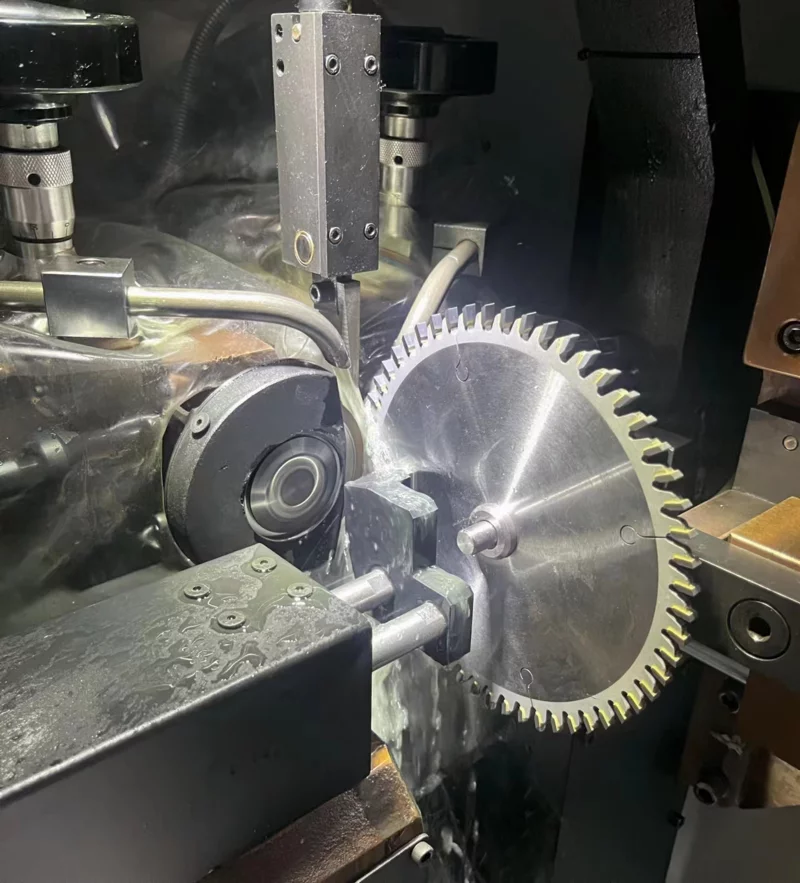

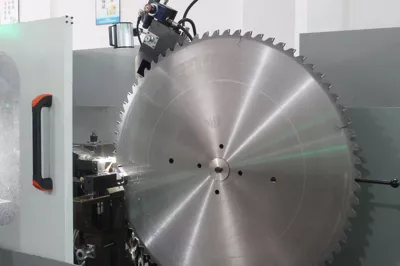

3. Retract the grinding wheel outward first to prevent the grinding wheel from hitting the teeth of the saw blade.

4. Install the saw blade on the machine and adjust the distance between the saw blade and the grinding wheel.

5. Adjust the handwheel to the angle at which the saw blade needs to be ground (Note: when adjusting the angle, the larger the angle when the grinding wheel moves to the left, and the smaller when moving to the right). Then try pulling a few teeth, measure with a dial indicator, and see if it matches the angle on the drawing. If it matches, grind the excess amount of alloy protrusion.

6. Measure the angle and protrusion amount with a dial indicator while grinding to avoid errors.

7. Repeat the above process until the saw blade is properly ground.

Process requirements, quality control requirements

1. The force applied to grinding the saw blade must be uniform and consistent (the speed must be uniform).

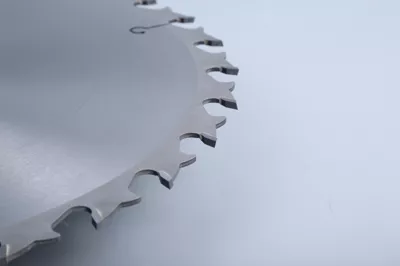

2. Protrusion tolerance: -0.02~0.04mm.

3. Protrusion fluctuation tolerance: 0.02mm.

4. Tolerances for the secondary cutting angle and the secondary relief angle: ±0.01°.

5. Tolerances for reducing the side cutting edge: ±0.03mm.

Maintenance precautions

1. Clean the equipment before and after work.

2. If there is any abnormal noise during equipment operation, stop immediately to check and troubleshoot before restarting.

3. Drain water from the pneumatic tri-coupler and refill with pneumatic oil when needed.

4. Add grease to the screw inside the equipment.

5. Check the hydraulic oil level and pressure, refill hydraulic oil if the level is low, and maintain oil pressure between 20~30Kg.

6. Check the equipment accuracy at least once, and repair immediately if it does not meet requirements.

7. When changing the grinding liquid, clean the water tank and water pump.

8. Coat unused saw blade core sleeves with rust prevention oil before storage.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.