Grinding Machine Operating Procedures Surface Grinding

I. Operating Procedures

1. Turn on the power switch and hydraulic pressure switch.

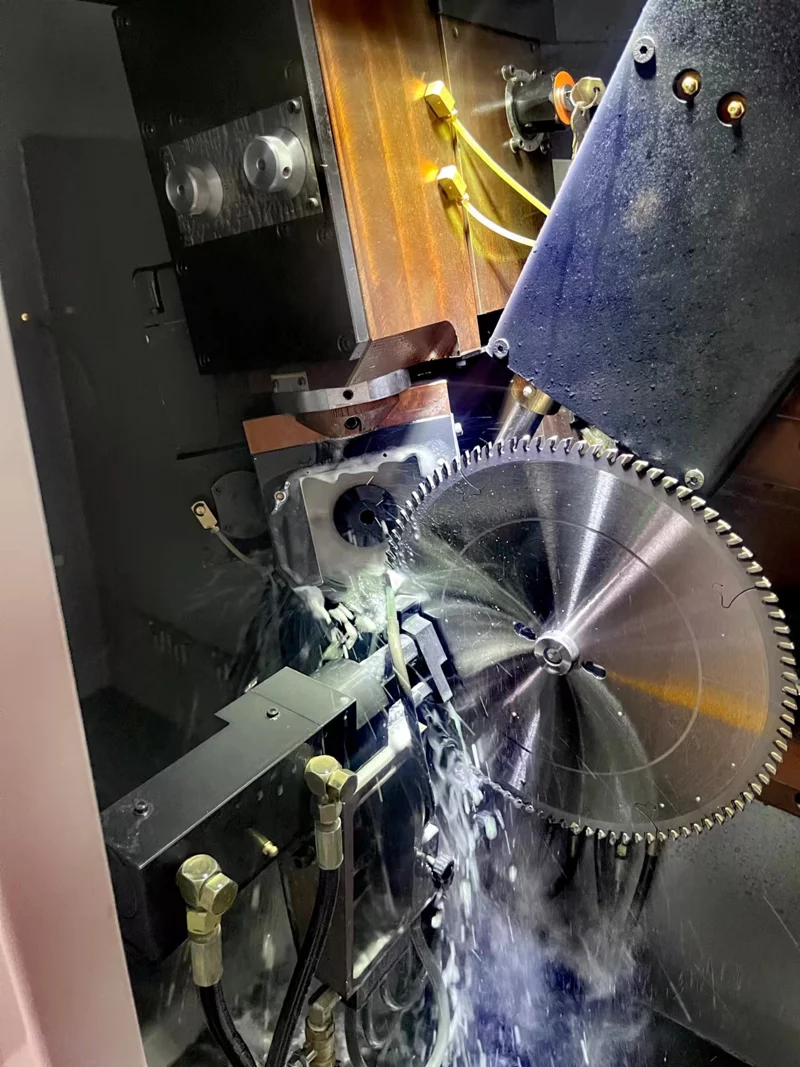

2. Check if the grinding wheel is worn, if worn it needs to be repaired or replaced.

3. Start the machine and let it idle for two minutes to check for any abnormalities.

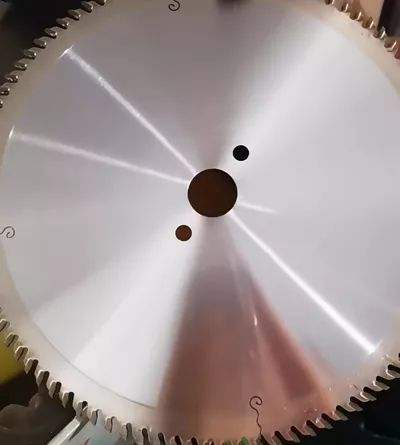

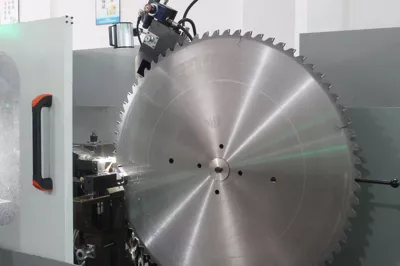

4. Select the appropriate core sleeve according to the inner hole of the saw blade (the gap between the inner hole and the core sleeve meets the tolerance requirements).

5. Measure the thickness of the saw plate and adjust the center position (ensuring the center line of the saw blade aligns with the center of the grinding wheel).

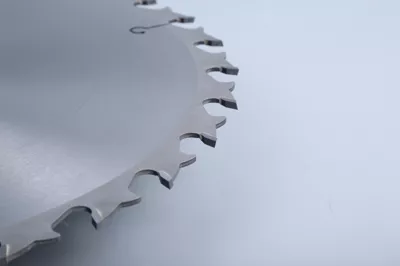

6. When mounting the saw plate on the push rod, adjust the tooth setting, loosen the hand wheel screw, adjust the tooth setting to the corresponding height of the alloy, and lock the hand wheel screw after adjusting.

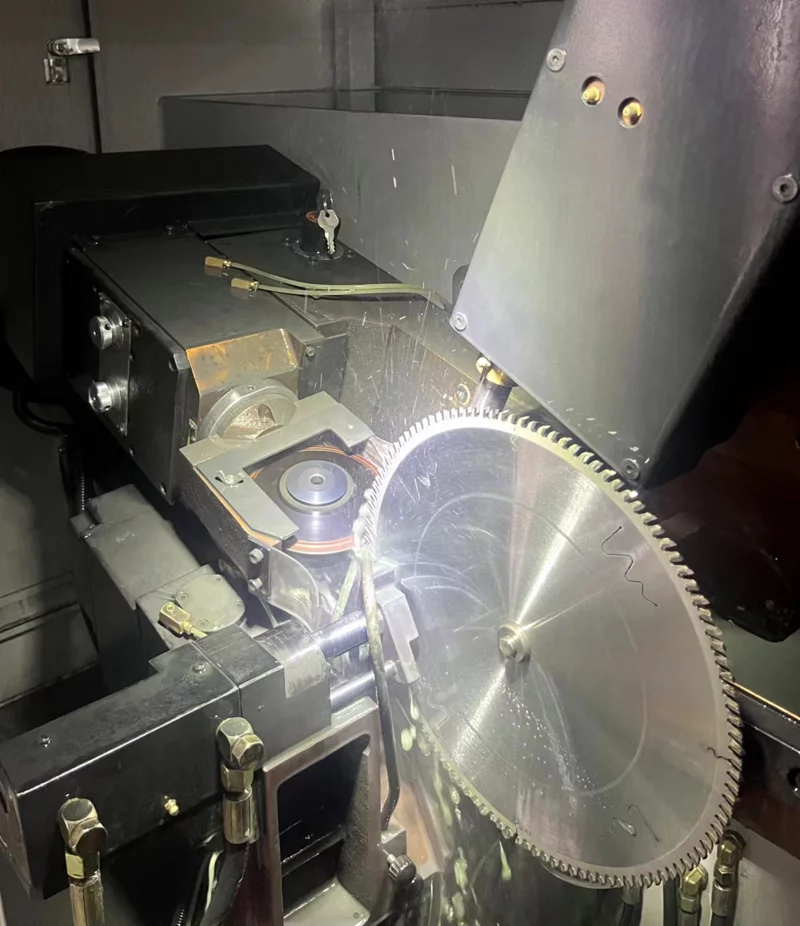

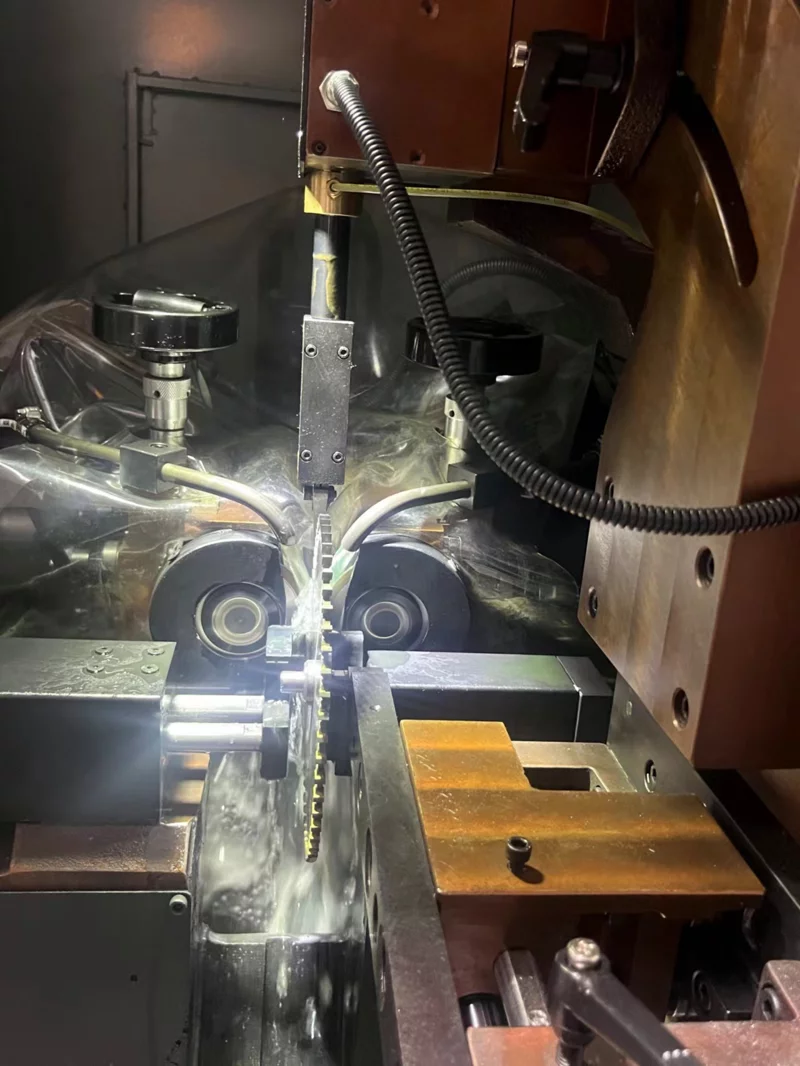

7. Engage the grinding wheel manually beyond the stroke of the alloy, then grind the alloy into a surface. Use a projector to check if the blade tilt angle matches the drawing without any distortion. If the blade tilt angle matches the drawing and has no distortion, the saw blade can be fully automatically processed.

8. Spray a large amount of grinding fluid onto the contact surface of the grinding wheel and the alloy to prevent damage to the grinding wheel and the alloy.

II. Process and Quality Control Requirements

1. Strictly control the single grinding amount.

2. Ensure the alloy is completely ground into a surface.

3. Blade tilt angle angle tolerance: ±0.5°

4. The single grinding amount generally does not exceed 0.02mm.

III. Maintenance Precautions

1. Clean the equipment before and after work.

2. If abnormal noises are heard during equipment operation, stop immediately for inspection and repair before using again.

3. Make sure to lubricate all lubrication points, and press out the old grease when adding new grease.

4. Check if the hydraulic oil level is near the minimum level line, top up immediately if necessary.

5. When replacing grinding fluid, clean the water tank and water pump.

6. Regularly check the equipment accuracy, and stop for maintenance if it does not meet the requirements. Only resume use after repair.

7. Coat unused core sleeves with rust-proof oil before storage.

8. Clean the suction cups thoroughly before use.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.