Circular saw blades sharpening correcting principles and methods (1)

Circular saw blades, sharpening, correcting principles and methods (1)

1. Why do saw blades need to be corrected?

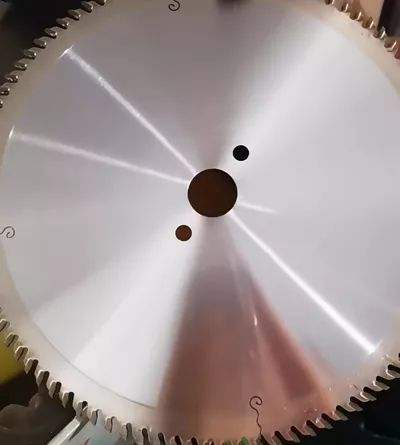

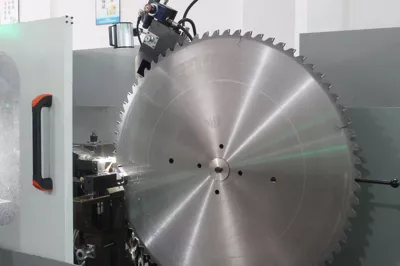

Answer: During the sawing process, in addition to the centrifugal force, the saw blade also generates heat through friction with the wood. Due to the significant difference in frictional heat between the blade's edge and middle section, the saw blade can expand and the edge can become loose, causing the blade to wobble. In some cases, the blade may exceed the permissible force of the material and develop cracks. For these reasons, correcting and adjusting the circular saw blade is an essential task, and the quality of the correction, the level of accuracy, directly affects the lifespan of the saw blade and the safety of the user.

2. Principles of correcting saw blades:

Answer: The horizontal correction of the saw blade is to make the blade flat. When the materials and thickness are uneven, a necessary step should be taken. This is because during the blade processing, thin plates with a wide area will have imbalanced stress due to heat treatment, even with a series of high-pressure measures, such as quenching and tempering. As a result, the blade may appear twisted or have surface irregularities. This issue can also occur during surface grinding, which can affect the outcome. After being used by the customer, the saw blade may also experience deformation, and the occurrence of such conditions is difficult to predict, making it crucial to subtly eliminate these imbalanced stresses. Operators, by using their sight and touch, can operate with sensitive judgment, manually correcting with their hands by using a straightedge and a hammer.

3. Why should circular saw blades have appropriate tension?

Answer: During cutting, the reciprocating motion of the saw means the circular saw blade undergoes rotational movement. Hence, besides experiencing frictional heat from the material, the circular saw blade is also subject to centrifugal force. The edge of the blade gradually expands due to this force, and the centrifugal force increases proportionally with the square of the rotation speed. Consequently, the edge section of a high-speed saw blade extends more than the middle section. As a result, the frictional heat generated at the blade's edge is greater, causing the edge to become loose. This instability leads to difficulties in cutting and the blade wobbling. To address this issue, the circular saw blade needs to have an appropriate tension, where the edge is "tighter" than the middle section. This way, during the cutting process, when frictional heat and centrifugal force cause the edge section to extend, it immediately stabilizes the saw blade. This is the purpose of tensioning the circular saw blade.

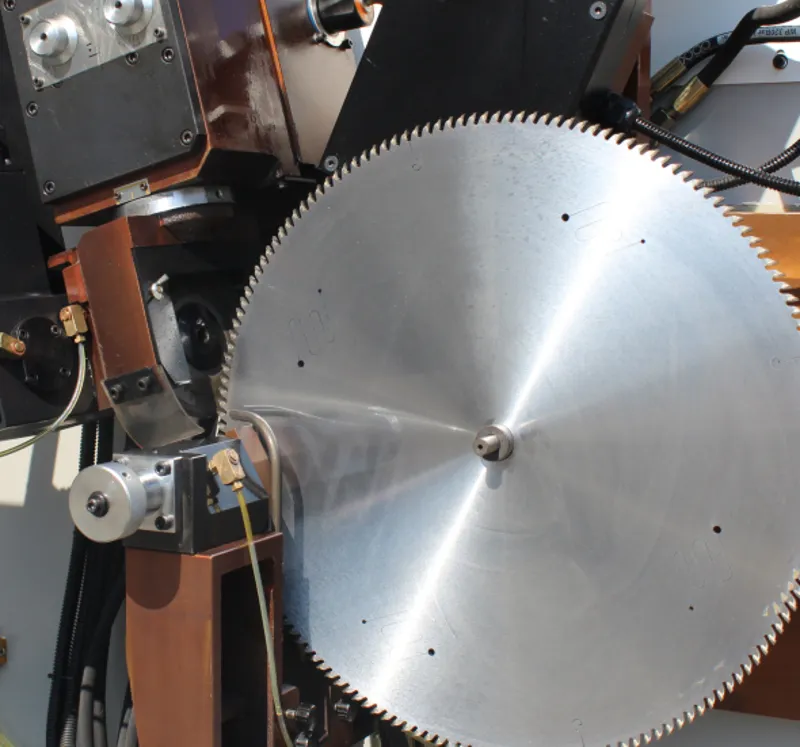

4. Sequence of correcting circular saw blades and tools used:

A. Shape inspection - dimension check - combination square and micrometer

B. Horizontal straightening - combination square, horizontal ruler, hammer and flat square

C. Tensioning horizontal correction - tensioning gauge, horizontal ruler, hammer and flat square

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.