Operation Procedure:

1. Turn on the power switch and air pressure switch, check if the air pressure is normal.

2. Start the machine and let it run empty for about 2 minutes, check if the mechanics are normal.

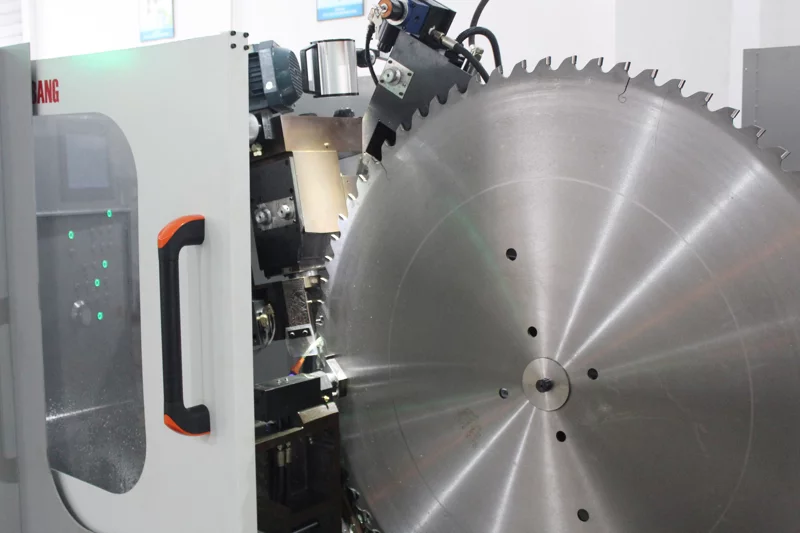

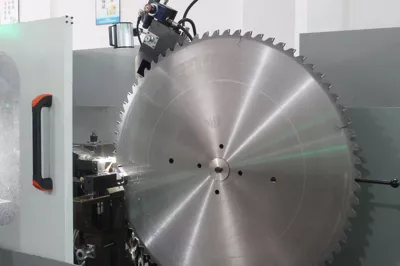

3. Select the appropriate core sleeve according to the inner hole of the saw blade (the gap between the inner hole and the core sleeve meets the standard requirements).

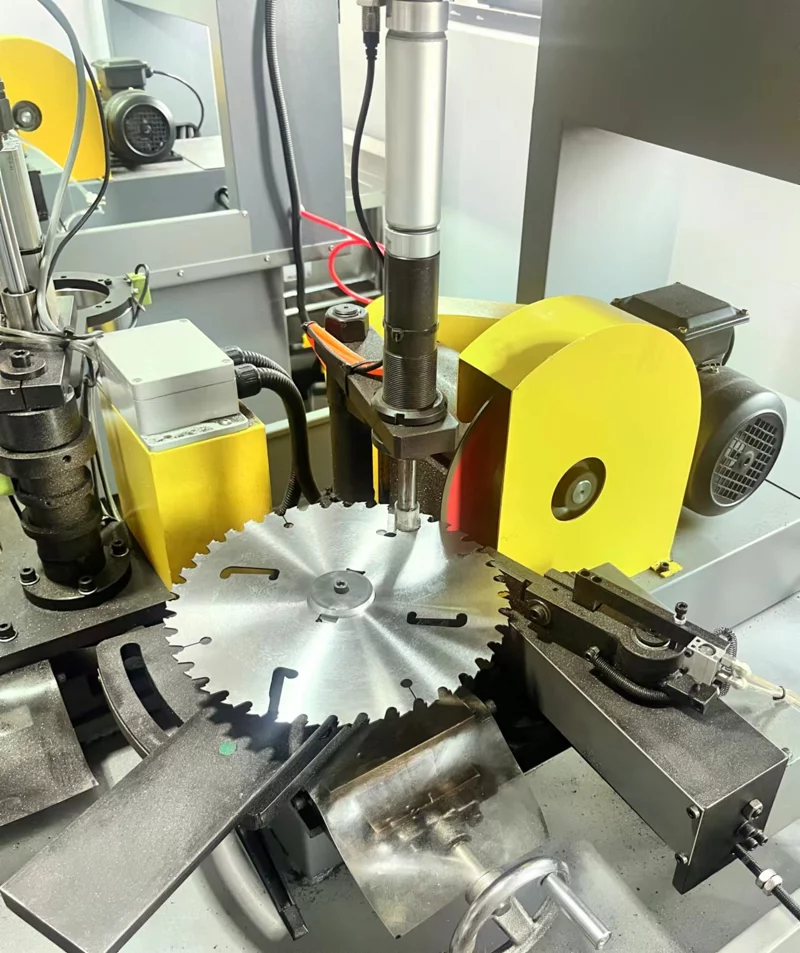

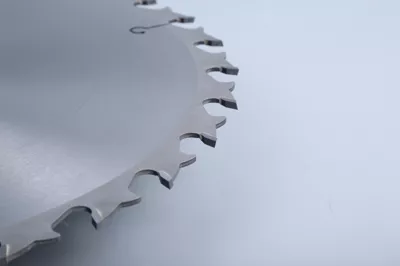

4. Install the saw blade, clamp the saw blade, and set the appropriate grinding position and front limit according to the angle required by the drawing (1. adjust the grinding wheel parallel to the gear root. 2. adjust the front limit between the grinding wheel and the gear root, the grinding wheel should just touch the gear root).

5. Adjust the gear wheel and check if each tooth belongs to normal.

6. Turn on the manual and water pump, and then turn on the automatic to grind a few teeth, take out the saw blade to check if the gear root is ground into one surface, then take it to the projector to check the angle, see if it is consistent with the drawing angle, and check for no burrs and blackening phenomena, the tooth groove surface should not be arc-shaped.

7. Install the corresponding cutter head for comparison, see if it reaches the appropriate depth (reserve height 1.5~2.0mm), if appropriate, install the saw blade to operate normally.

8. After processing, the saw blade must be cleaned with rust preventive liquid and placed on an iron rack to dry.

Process requirements, quality control requirements:

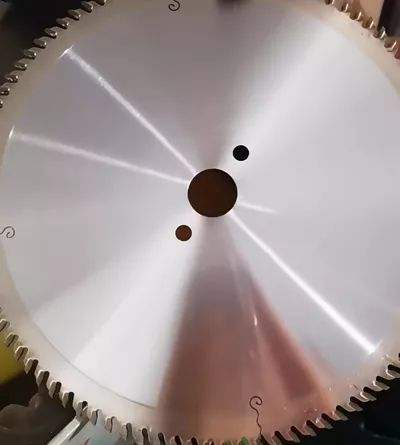

1. The angle dimensions of the gear root must match the corresponding drawing angle (or ±0.1°).

2. The saw blade should not have burrs, blackening phenomena, or arc-shaped surfaces.

3. The cutter head should be 1.5~2.0mm higher than the ground gear root.

Maintenance precautions:

1. Clean the equipment before and after work.

2. Drain water from the air triplet and replenish pneumatic oil if it is insufficient.

3. Do not stack any debris on the machine.

4. Apply lubricating oil to all sliding parts of the machine.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.