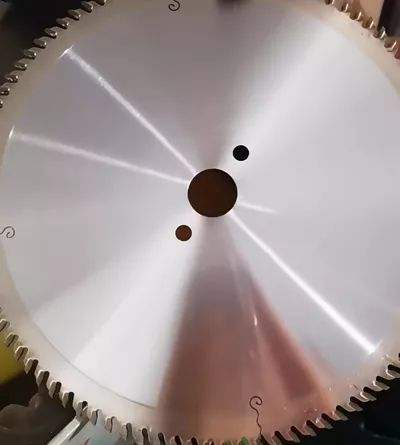

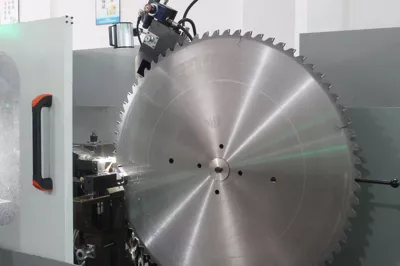

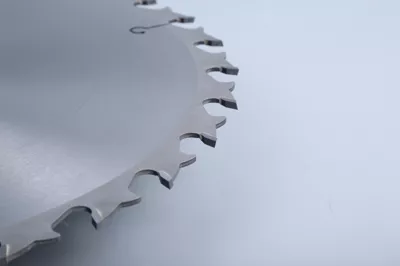

Application of ball screw in grinding equipment of cemented carbide circular saw blade

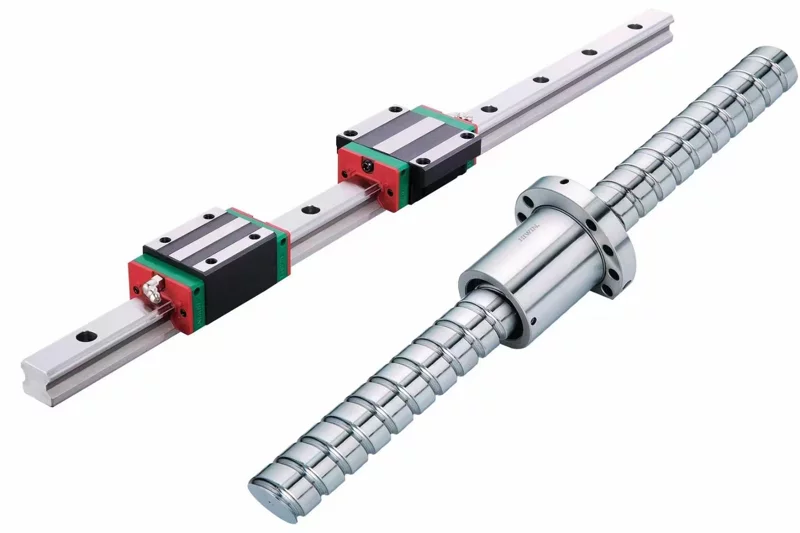

Lingbang Machinery manufactures alloy circular saw blade grinding equipment, all of which utilize imported precision grinding ball screw rods to enhance equipment accuracy, stability, lifespan, and efficiency, while reducing maintenance and operational costs, thereby elevating the company's competitiveness and market position.

The advantages of Lingbang machinery equipment employing imported precision grinding ball screw rods are as follows:

1. **High Precision**:

Precision grinding ball screw rods offer accuracy at the micron level, ensuring operational precision and stability.

2. **Long Lifespan**:

These screw rods boast an extended lifespan, often surpassing several hundred thousand cycles, reducing maintenance and replacement frequencies, thereby lowering operational costs.

3. **Low Friction and Wear**:

Their design minimizes friction and wear, enhancing equipment motion smoothness and precision, while increasing energy efficiency.

4. **Low Noise and Vibration**:

They reduce noise and vibration during equipment operation, enhancing efficiency and stability.

5. **High Efficiency**:

Their design enhances equipment efficiency, reducing production costs.

In international standards, screw rods are typically categorized into multiple grades (such as C0, C1, C3, C5, C7, and C10), with C0 grade offering the highest precision. The core components of Lingbang circular saw blade grinding machines adopt C5 grade screw rods, with a repeat positioning accuracy of ±0.005mm.

Welcome to browse more about circular saw blade grinding equipment page, please click...

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.