1. Structure of the Worm Gear Tooth Grinding Machine

The worm gear tooth grinding machine consists of a worm gear and a worm wheel. The worm gear is a spiral-shaped cylinder, while the worm wheel is a gear embedded within a segment of the worm gear. The worm wheel usually has fewer teeth, typically 1-4, while the worm gear has a larger helix angle, usually ranging from 10 to 70 degrees.

Grinding stroke: 15mm

Pitch: 7mm - 120mm

Grinding speed: 0.5mm/s - 6mm/s

Processing diameter: 100mm - 650mm

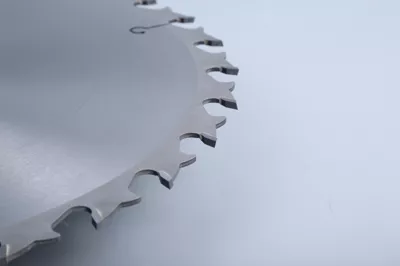

Metal circular saw blade grinding machine

Inquiry

2. Working Principle of the Worm Gear Tooth Grinding Machine

When the worm gear rotates, due to the spiral shape of the worm gear, the worm wheel can only rotate 1 tooth pitch or an angle of 1/number of worm wheel teeth after one revolution of the worm gear. Therefore, after one revolution of the worm gear, the worm wheel only rotates one tooth pitch, which means that the speed of the worm wheel is very slow. However, the worm gear can easily transmit a large amount of torque, making the worm gear tooth grinding machine suitable for applications that require slow speed and high torque.

At the same time, during the working process of the worm gear tooth grinding machine, due to the large helix angle of the worm gear, the contact area between the worm gear and the worm wheel is small, resulting in relatively low friction loss. Moreover, the teeth of the worm gear and the worm wheel are in mutual engagement, with the inclined surface of the worm wheel tooth slot parallel to the spiral surface of the worm gear. This ensures relatively smooth motion between the worm gear and the worm wheel.

3. Range of Use of the Worm Gear Tooth Grinding Machine

The worm gear tooth grinding machine is characterized by its ability to transmit large torque while maintaining low-speed rotation. Therefore, it is widely used in various industrial fields, such as lifting machinery, conveying machinery, petrochemical equipment, machine tools, and other mechanical equipment. During the transmission process, it is generally necessary to lubricate the worm gear tooth grinding machine to reduce friction generated during motion.

[Conclusion]

The worm gear tooth grinding machine is a commonly used mechanical transmission device, characterized by low speed and high torque, suitable for various industrial fields. Through the mutual engagement between the worm gear and the worm wheel, the worm gear tooth grinding machine achieves reliable transmission, and proper lubrication is required during use.