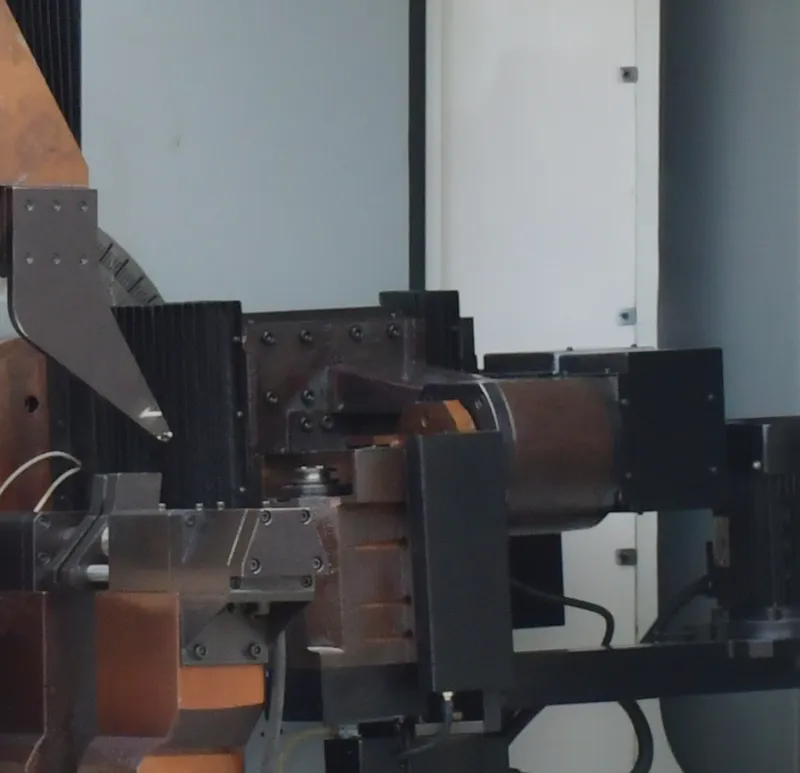

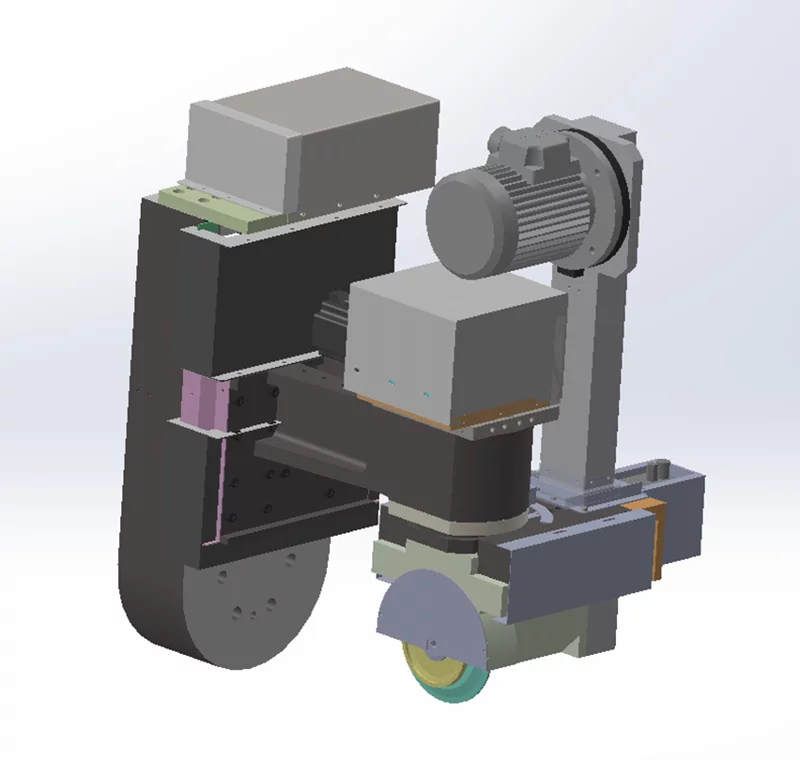

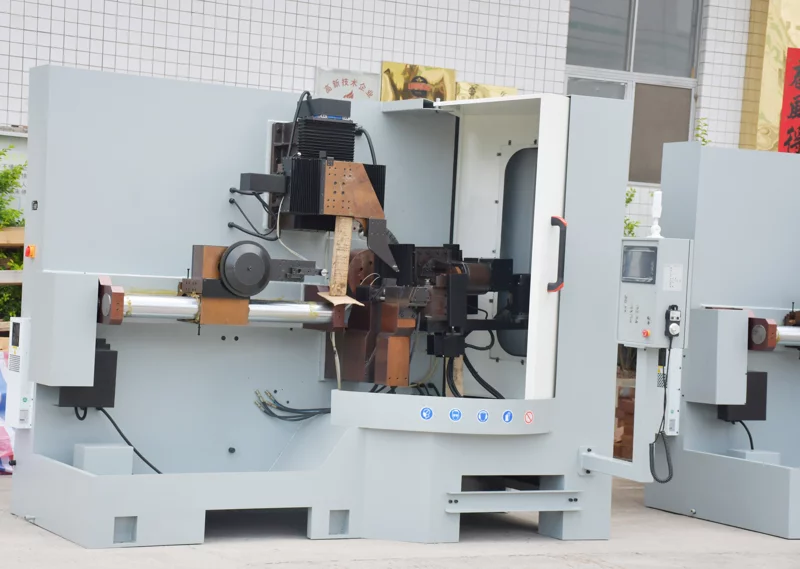

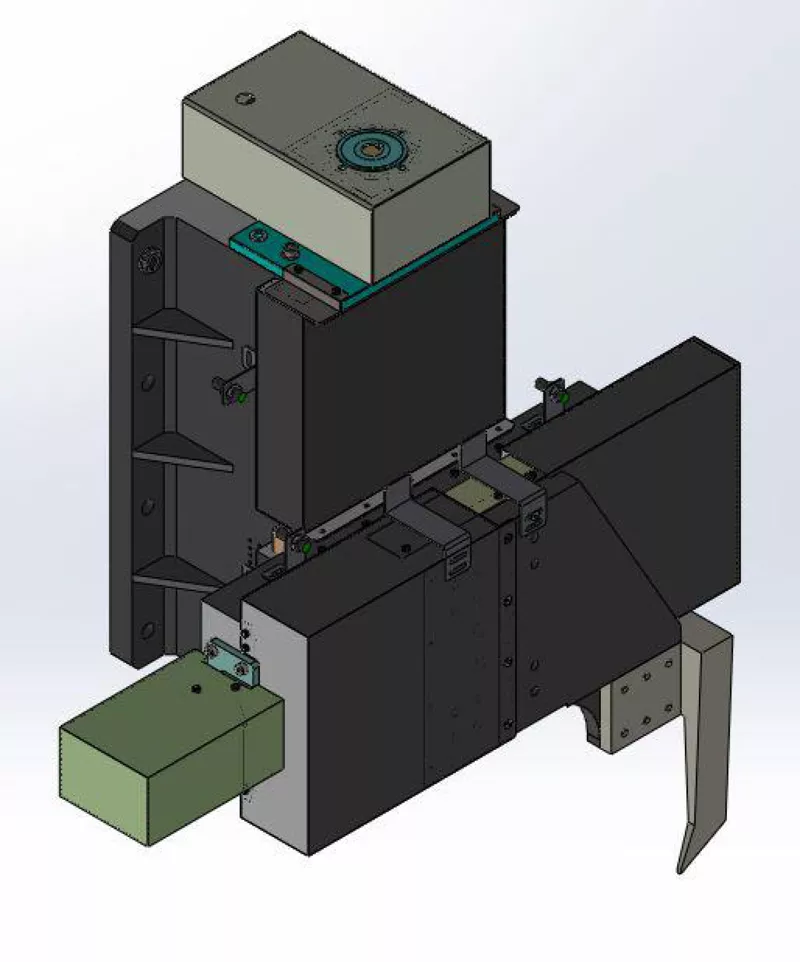

DMX2500 Face and top grinding machine

Basic Attributes

- Blade Outside diameter 500-2500 mm

- Bore hole diameter 30-205 mm

- Max blade thickness 15 mm

- Tooth Pitch 16-150 mm

- Rake angle -10~40 °

- Clearance Angle 10-45 °

- Bevel grinding top&face 45 °

- Grinding speed 0.8-6 mm

- Feeding Speed 7 tooth/min

- Grinding wheel outside dia. 125(T)/180(F) mm

- Grinding wheel linear speed 30 mm

- Coolant tank capacity 200 L

- Total power 6.5 kW

- Machine Size 3300*2150*2550 mm²

- Package size 3560*2330*2700 mm²

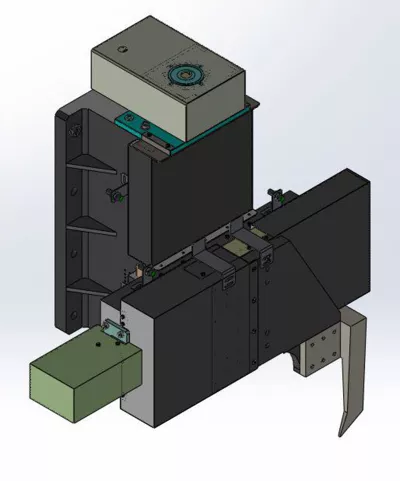

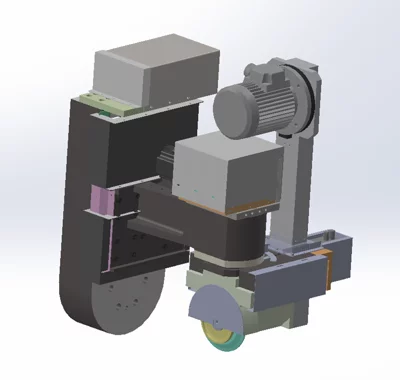

The machine adopts 4 CNC control axes to achieve precise gear adjustment and precise grinding, and almost all tooth shapes can be used in the machine Complete in one loop.

Easy to use with the innovative multi-function handwheel.

Innovative machine tool design concept efficiently realizes wood, aluminum, metal, plastic and other types of saw blades.

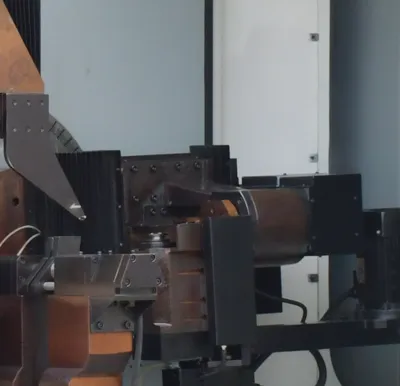

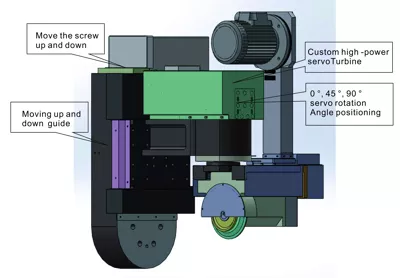

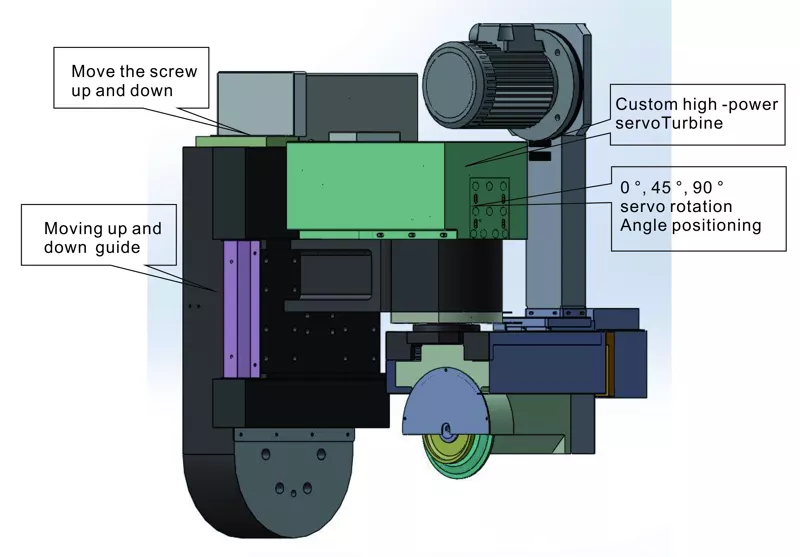

Servo motor driven face/top Angle adjustment for quick conversion from tooth face to top.

This machine is suitable for grinding the tooth tip, tooth surface and tooth surface of steel pipe circular saw blade. The main features are as follows:

1. Four kinds of grinding procedures are set independently, and each type is up to a variety of tooth combinations.

2. The equipment can automatically complete four types of grinding after one adjustment.

3. Two CNC gear axes, with arc gear function.

4. Four CNC grinding control axes, high-precision coordinated control to ensure grinding accuracy and efficiency.

5. The operation is simple, and the grinding programming can be completed by inputting data in the operation panel.

6. No adjustment of matrix thickness.

7. Grinding speed and stroke can be set arbitrarily.

8. The equipment has water-cooled and oil-cooled grinding methods.

For more information about alloy circular saw blade manufacturing equipment, please click