Hard alloy saw blade series four How to distinguish

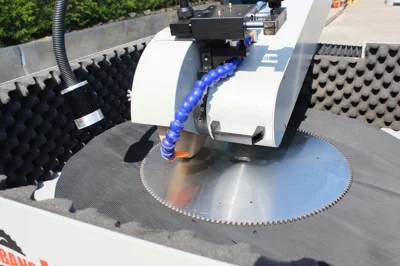

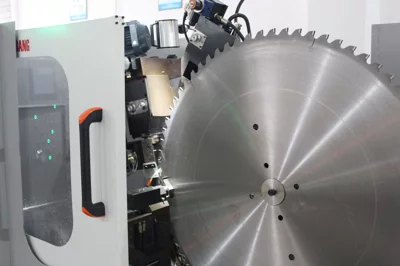

Usually, hard alloy saw blades are composed of saw plates and hard alloy saw teeth. Currently, hard alloy saw teeth are basically imported. The alloy particles used in high-quality saw blades are thicker and larger, because these alloy saw teeth can be ground multiple times, have a long service life, and the welding quality of hard alloy is also very important. The weld seam should be thin and even so that the saw teeth can withstand greater cutting forces.

The quality of the saw blade plate is very important. Because the saw blade rotates during cutting, it must not only transmit cutting forces but also maintain stability during work. Excellent saw blades not only have static geometric dimensions and accuracy, but more importantly, their dynamic characteristics.

Unlike diamond saw blades, when a hard alloy saw blade continuously cuts, the heat generated by cutting with alloy teeth will be conducted to the saw plate, causing the temperature of the saw plate to rise. In this case, high-quality saw plates can still maintain positional accuracy, while poor-quality saw blades may cause the saw plate to warp, affecting cutting accuracy. The dynamic stability of the saw plate is particularly important for the precise use of saw blades in groups.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.